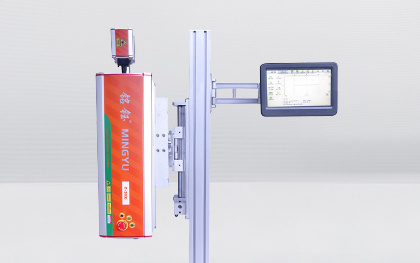

Mingyu Laser marking machine use and maintenance guide

Release time:2024-08-19

Mingyu Laser marking machine use and maintenance guide

In order to ensure the normal operation of Mingyu laser marking machine and extend its service life, we provide you with the following use and maintenance guidelines:

1. Cut off the power supply

When the laser marking machine is not working, the power supply of the marking machine and the computer should be cut off to avoid unnecessary energy waste and potential safety hazards.

2. Protect the lens

When not using Mingyu laser marking machine, please cover the field mirror lens to prevent dust contamination of the optical lens, to ensure that the performance of the equipment is not affected when the next use.

3. Non-professional personnel do not repair

Because the circuit of the laser marking machine is in a high voltage state when working, non-professionals should not be repaired when starting, so as to avoid electric shock accidents and ensure personal safety.

4. Cut off the power supply immediately

If there is any fault in the laser marking machine, please cut off the power immediately to avoid further expansion of the fault, and contact professionals in time for maintenance.

5. Clean the focusing mirror regularly

After prolonged use, dust in the air may be adsorbed on the surface of the lower end of the focusing mirror. This may reduce the power of the laser and affect the marking effect; In severe cases, it may even cause optical lenses to overheat and burst. Therefore, when the marking effect is not good, you should carefully check whether the surface of the focusing mirror is contaminated.

6. Clean the focusing mirror

If the surface of the focusing mirror is contaminated, remove the focusing mirror and clean its lower surface. Please note that special care should be taken when removing and cleaning the focusing mirror to avoid damage or injuries from falls, and to avoid touching the mirror surface with your hands or other objects.

7. Cleaning method

When cleaning the focusing mirror, use a 3:1 mixture of anhydrous ethanol (analytical pure) and ether (analytical pure). Dip a long fiber cotton swab or lens paper into the mixture and gently scrub the surface of the lower end of the focusing lens. Each wipe side, you must replace the cotton swab or lens paper once to ensure the cleaning effect.

8. Avoid moving the machine

In the working process of the laser marking machine, do not move the machine, so as not to damage the internal precision parts and affect the normal use of the equipment.

9. Maintain ventilation and heat dissipation

Do not cover or stack other items on the laser marking machine to ensure that the machine has a good ventilation and heat dissipation effect to prevent the equipment from overheating and damage.

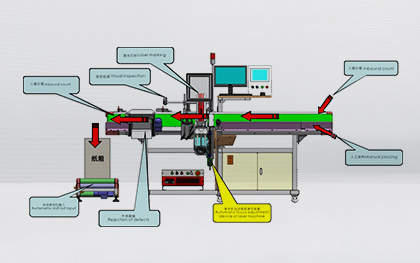

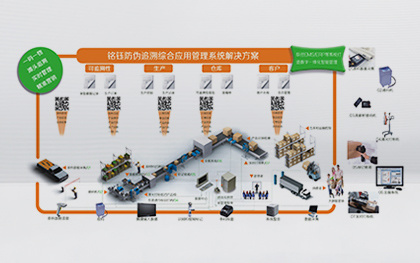

KEYWORDS:UV laser marking machine,Large format laser marking machine,Pipeline laser marking machine,Plastic laser marking machine,Purple laser marking machine

Keywords:Jinan laser marking machine,3D laser marking machine,Small laser marking machine,Price of laser marking machine,Rotating laser marking machine,Carbon dioxide laser marking machine,Plastic laser marking machine,Pipeline laser marking machine,UV laser marking machine

Previous Page

News classification

Related News

Related News