Category

Non-standard automation

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Non-standard automation

|

For Heshan Liansu Pipe Fittings Workshop |

|

|

Use |

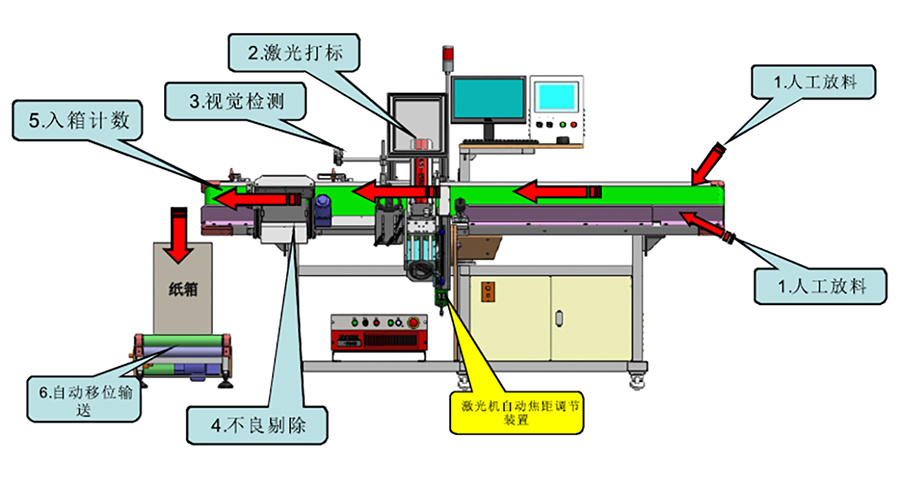

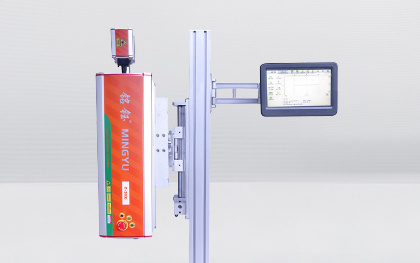

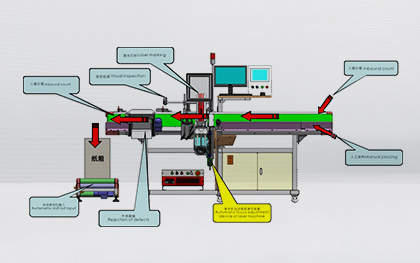

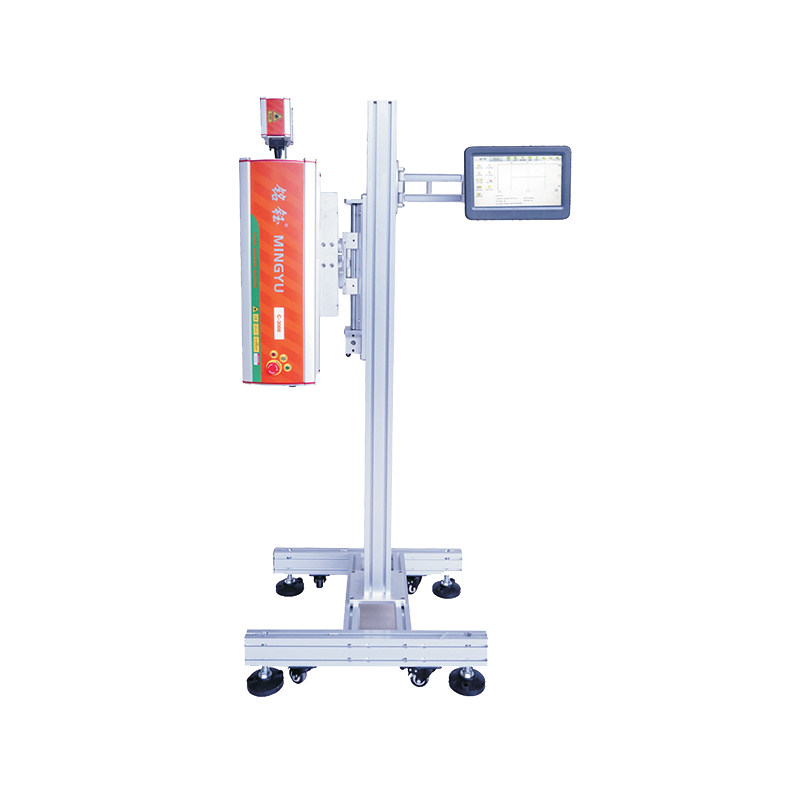

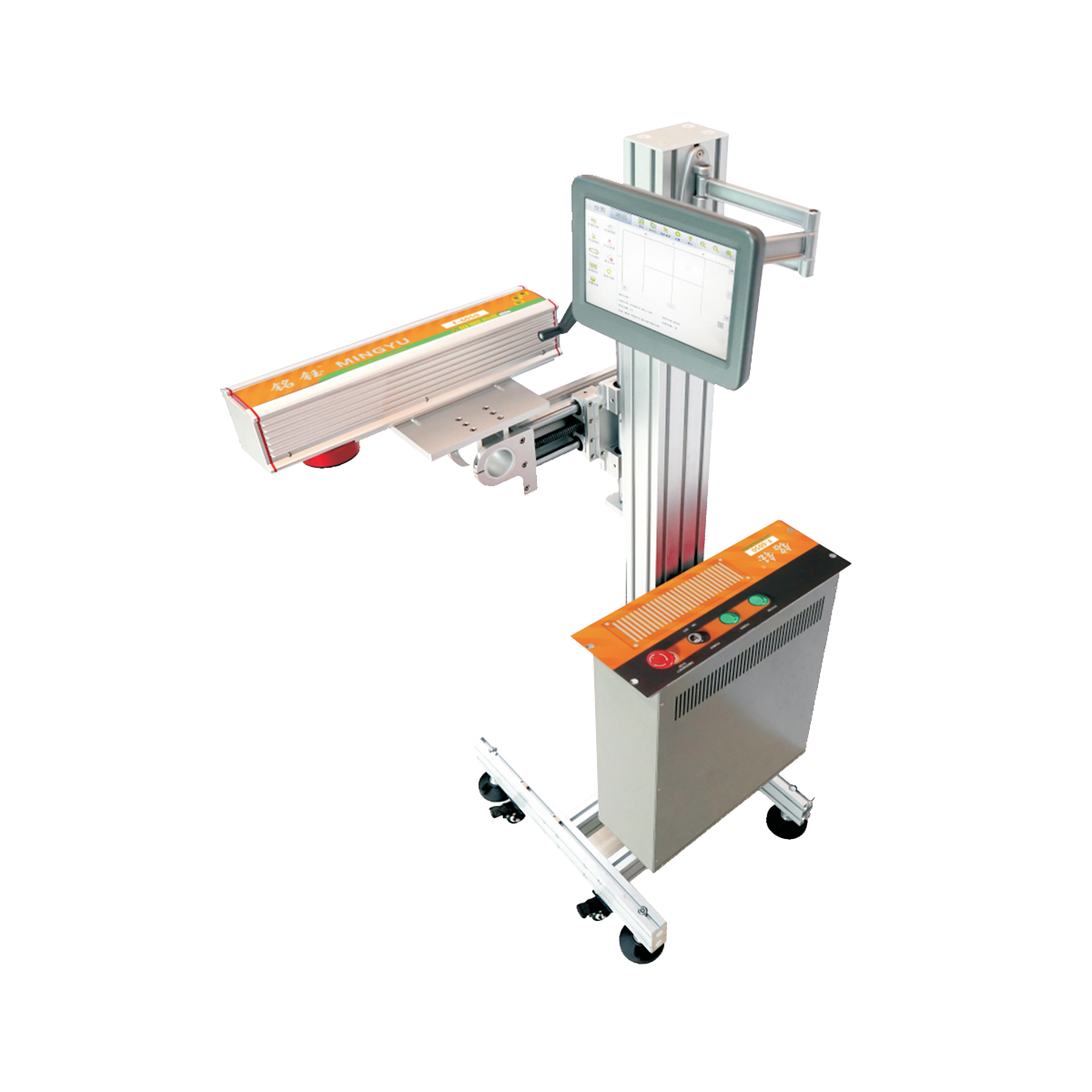

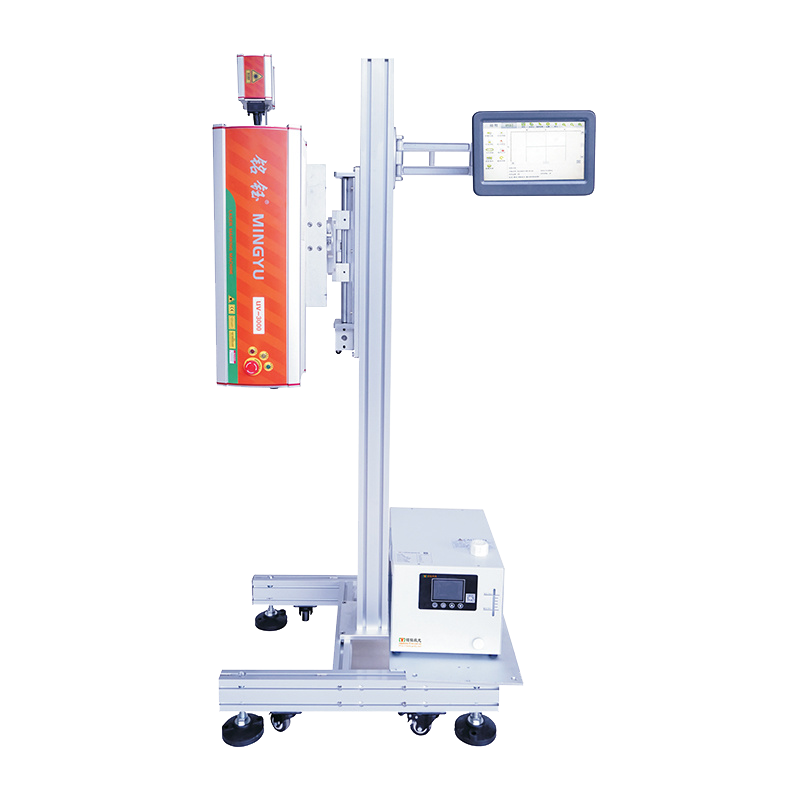

Marking of surface identification of various PVC pipe fittings (e. g. elbow/straight-through/tee, etc.), barcode reading and defective elimination |

|

Design and manufacture of non-standard line body |

Non-standard line equipment is the user-customized, the only automation system integration equipment, is the use of the unified industry standards and specifications issued by the state manufacturing unit equipment assembly, according to the customer's use needs, development and design of manufacturing equipment. Different types of customers have different process requirements. |

|

Non-standard line body application |

Non-standard line body equipment due to the particularity of its products, so that it also has a wide range of applications. The main application industries are Production, transportation and packaging in the food industry Production Conveyor in Processing Manufacturing Product delivery of electronic and electrical production line Application of Storage Facilities in Logistics Industry Manufacturing and installation of auto parts |

|

Advantages |

Custom Design Enhance the corporate image according improve labor intensity save production cost Improve production efficiency improve product quality |

|

Non-standard line body application list |

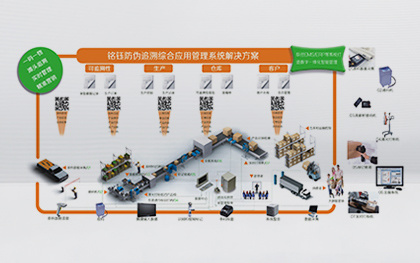

Liansu Company needs to attach bar code information to pipes and joints of various shapes, and detect and reject unqualified products. A single laser marking machine and inkjet printer cannot print bar codes for products of different shapes. Therefore, Mingyu Company has designed a set of non-standard wire body equipment for Liansu Pipeline, which can complete coding of products of various shapes, product defect detection and custom quantity packaging in one set of equipment. After applying the system, Liansu significantly reduced the complexity of the production process and production costs, greatly improved production efficiency, and perfectly solved customer problems. |