Category

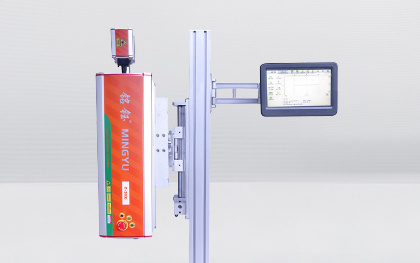

Laser marking machine equipment

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

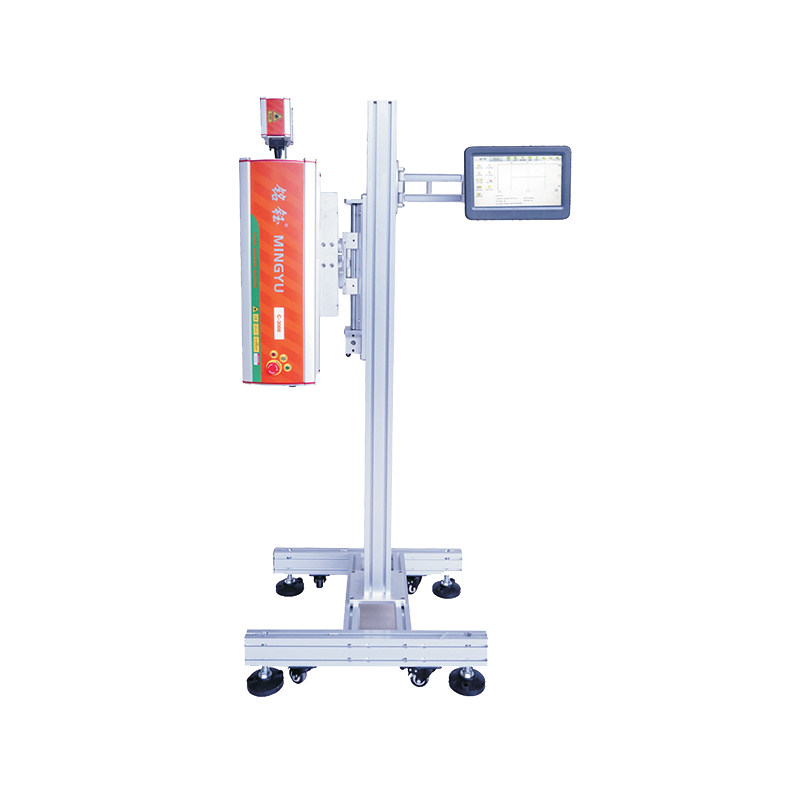

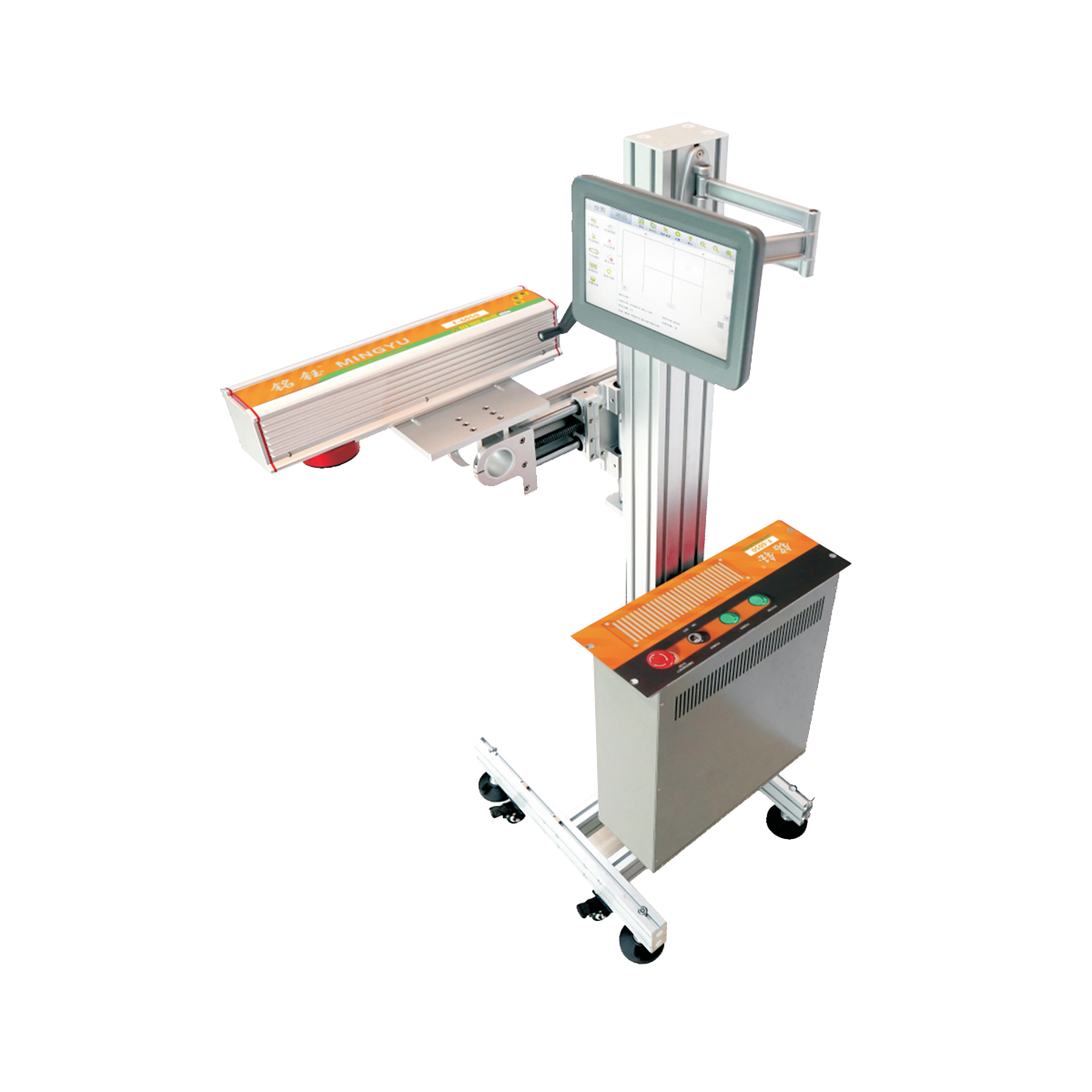

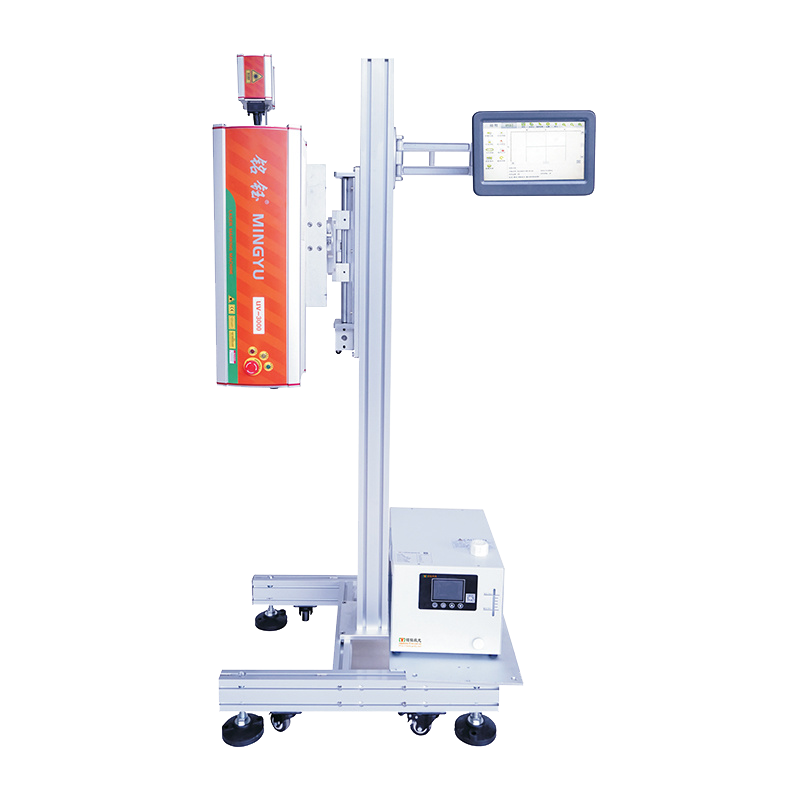

Laser marking machine equipment

| Main technical parameters: |

| Power input requirements: 110-220 50/60HZ |

| Equipment power consumption:<1000W |

| Machine material and weight: aluminum alloy, 30KG |

| Laser power: 30W, air-cooled, life ≥ 45000 hours |

| Control system: embedded Linux system, touch screen control |

| External interface: I/O, USB, serial port, network port |

| Marking range: 75mm * 75mm, optional maximum range 600mm * 600mm |

| Marking speed: ≤ 18000mm /s |

| Repeat precision (RMS): <2 urad |

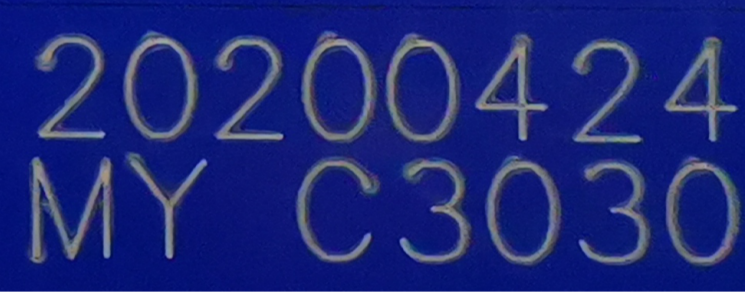

laser marking machine:

It is to use a laser beam to make permanent marks on the surface of various substances. The effect of marking is to expose deep substances through the evaporation of surface substances, or to "carve" traces through the chemical and physical changes of surface substances caused by light energy, or to burn off some substances through light energy to display the graphics and characters to be etched.

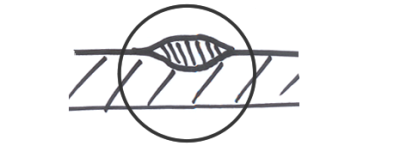

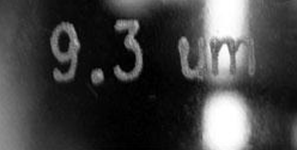

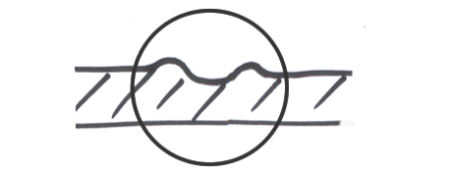

CO2 laser machine characteristic application:

Wavelength of 10.6μm vs. 9.3μm on PET

|

|

|

|

Wavelength of 10.2μm and 10.6μm in coated paper

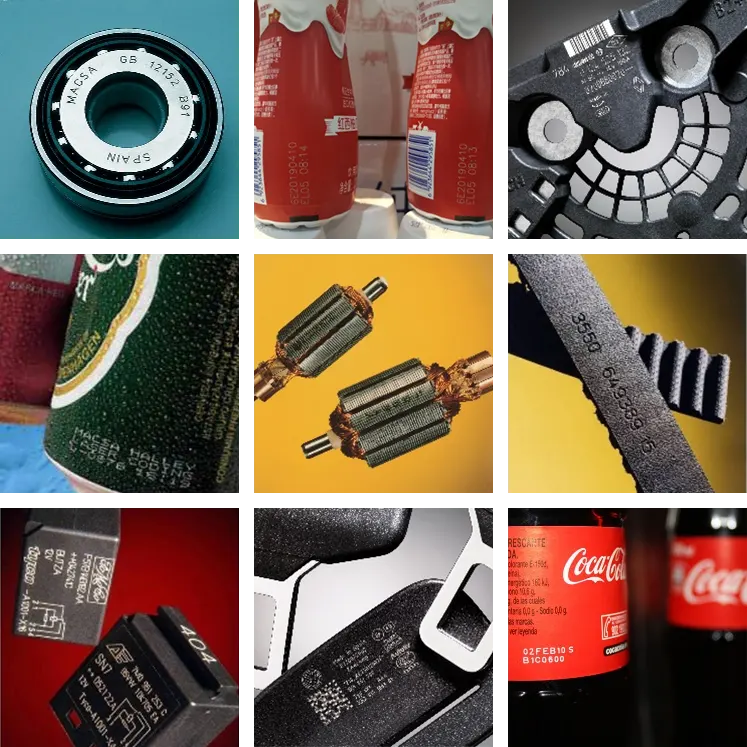

C- 3000 series laser machine applicable material:

Paper products, labels, wood products, glass, PET, plastic products, ceramics, leather, cloth, coated metal products, etc.

Widely used:

Wine, water, beverages, grain and oil, medicine, daily chemicals, ceramics, toys and many other fields.

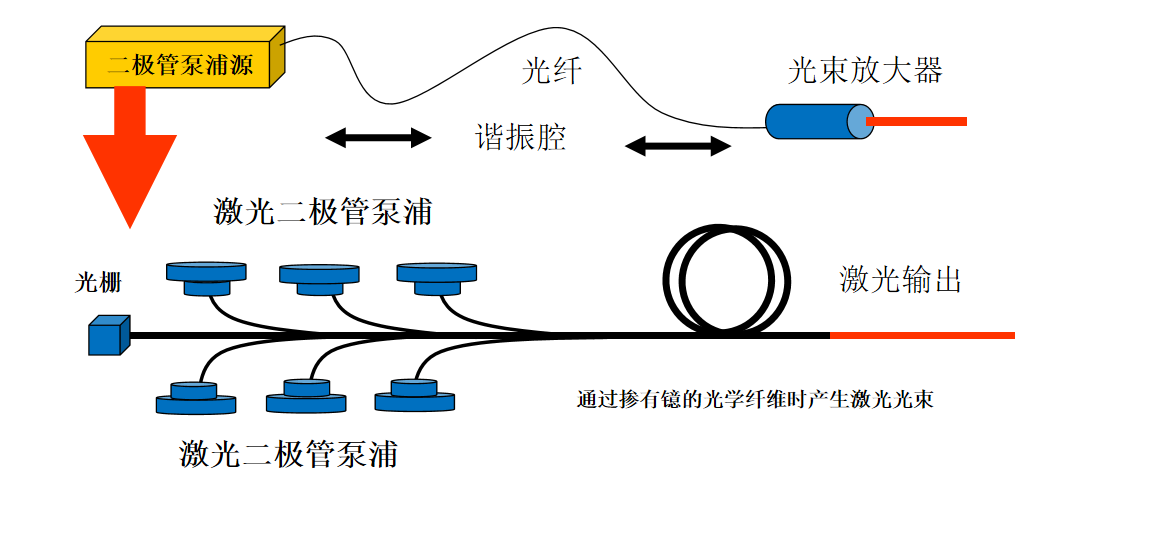

Optical Fiber Technology 1064nm

fiber laser machine application:

Cans, paper products, metal, plastic, rubber, glass, flexible packaging film and other materials.

Widely used: building materials, auto parts, hardware and electronics, medicine, soft bag food, daily chemical, mechanical processing, aerospace and other fields.

UV laser marking technology

Laser marking machine using ultraviolet laser, compared with infrared laser, ultraviolet light focus spot is very small, can greatly reduce the mechanical deformation of the material and processing heat effect is small, belongs to the cold processing.

"Cold working" (ultraviolet) photons with high load energy can break chemical bonds in materials (especially organic materials) or surrounding media, cold peeling, and color difference changes in materials. The side effect of "heat damage" in the processing area is minimal. Suitable for fine processing, high clean processing should be.

|

|

|

|

Schematic diagram of molecular chemical bonds |

Schematic diagram of chemical bond breakage |

Schematic diagram of molecular fission |

UV laser machine application:

Bottles, cans, paper products, metals, composite films, glass, polymer materials, high-density synthetic materials, PE/PET/PS and other materials.

Widely used: beverage, dairy products, hardware and electronics, chip industry, medicine, building materials, daily chemical, aerospace and other fields.