Category

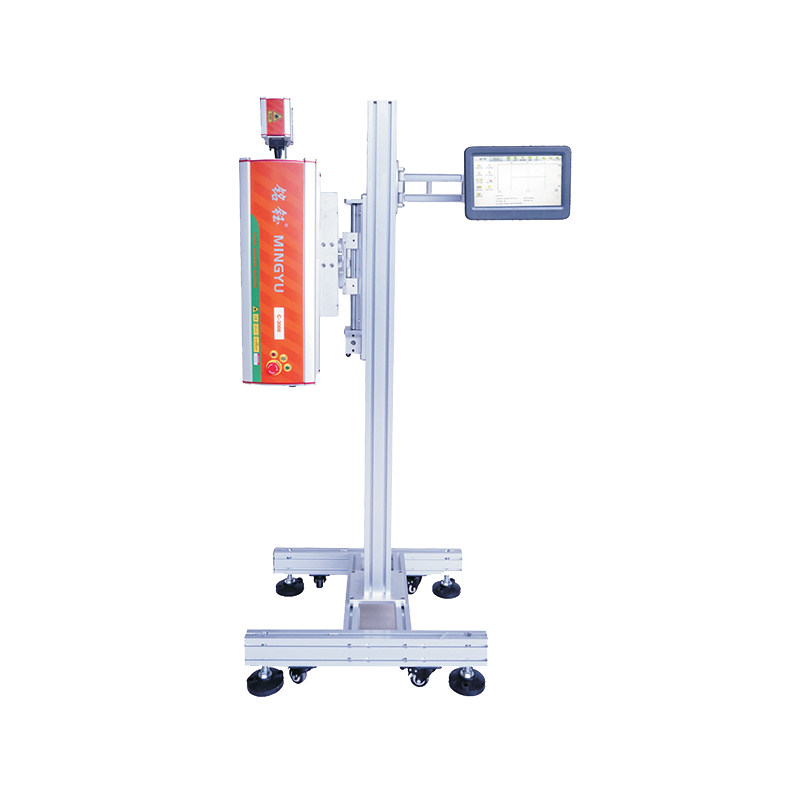

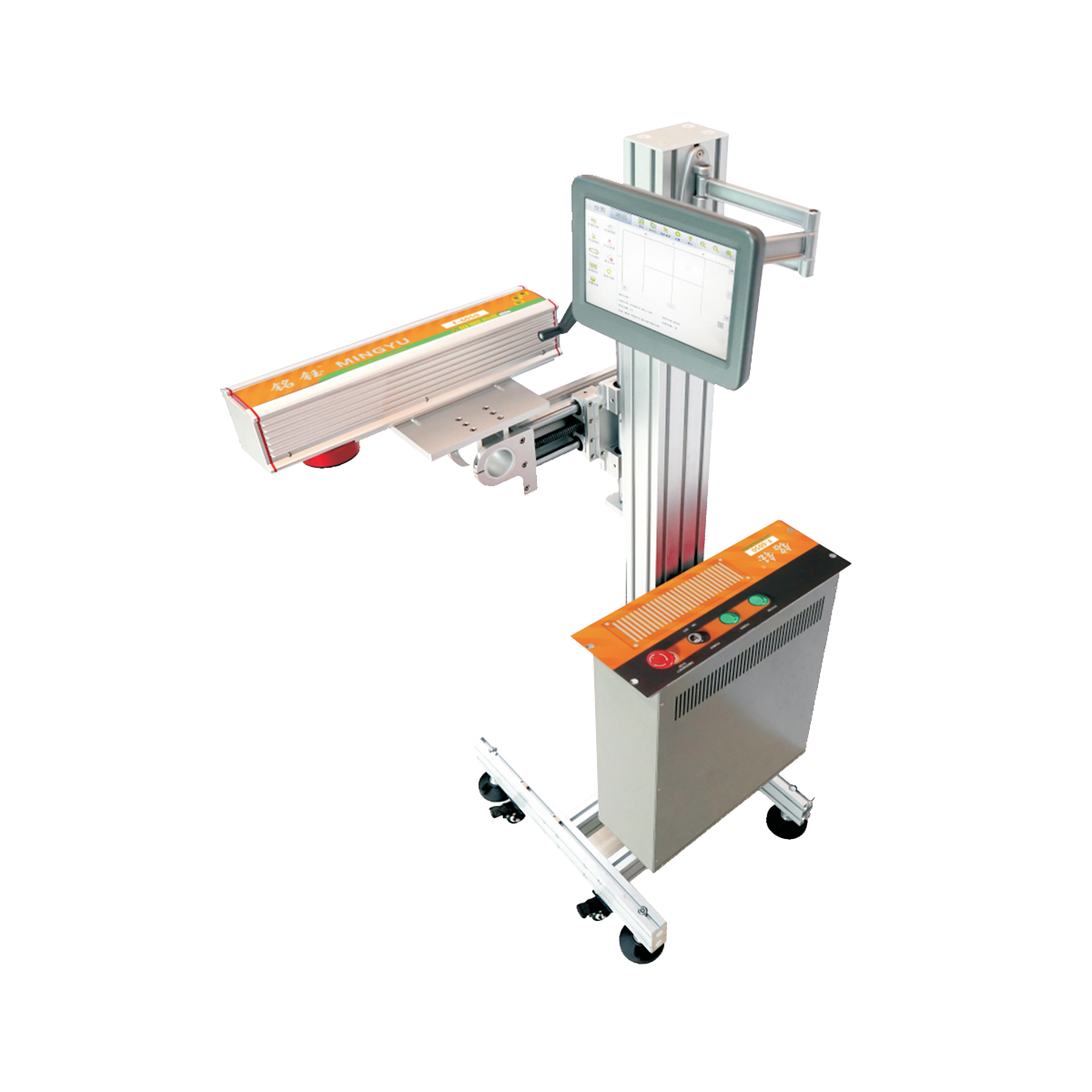

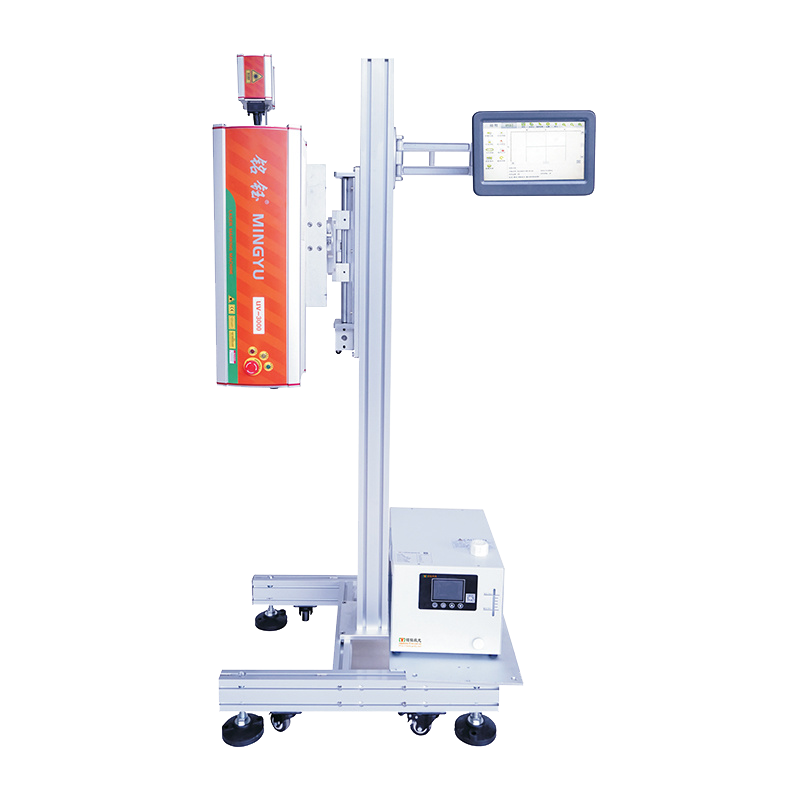

Ink inkjet printer equipment

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Ink inkjet printer equipment

|

Spray code features: |

Contains important product information, production time, origin, tank number, etc; |

|

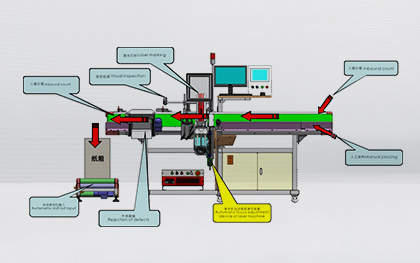

Current status of testing: |

Manual detection has problems such as blind area, fatigue and inability to adapt to height; |

|

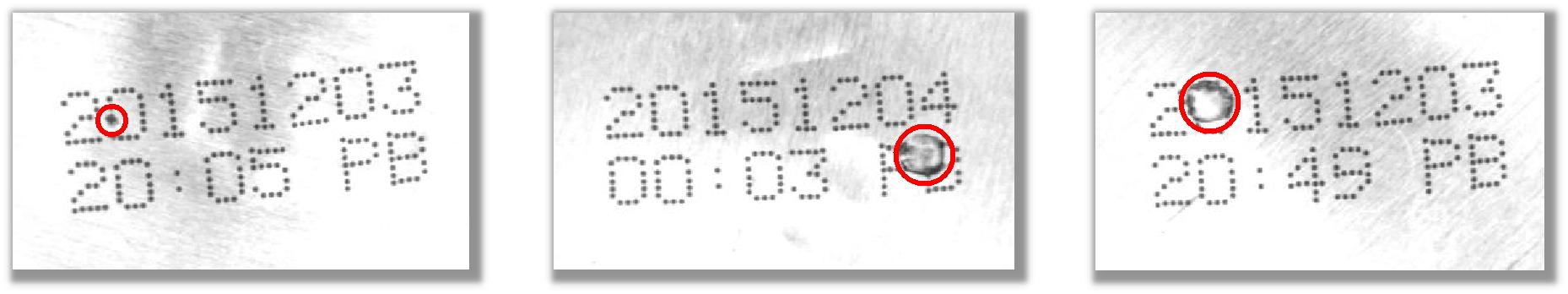

Detection difficulties: |

The background of the spray code is complicated and there are many kinds of patterns; |

|

1, different brands of inkjet printer, font there are differences. |

|

Schematic diagram of inkjet printing effect under different conditions

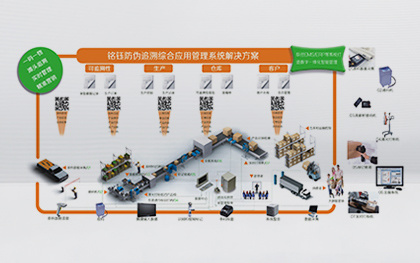

Suggestion: According to the printing characteristics of ink inkjet printer, it is necessary to make standard management and clear standards for on-site inkjet before supporting visual inspection. Visual inspection can be modeled and tested according to the requirements of on-site operation specifications, improving the quality of product printing from the source, improving various inspection indexes of visual inspection and reducing the rejection rate.

| Classification | Test Items | Accuracy | detection rate |

| A | Single character printing error | Character error | 100% |

| B | Single character print missing | Missing 100% | 100% |

| Missing 50% | 99% | ||

| C | Overall character defect | No spray code | 100% |

| Overall missing 30% | 99.9% | ||

| Excessive position offset | 99.9% | ||

| D | Comparison and detection with system information | Inconsistent with system information | 100% |