Mingyu Laser: Innovate micro-welding technology and lead the new trend of the industry

Release time:2024-08-24

1. Current status and challenges of electrical connection technology

Electrical connection technology, as the cornerstone of the electrical industry, has been constantly seeking breakthroughs and development. However, with the increasing cost, performance and volume requirements of connection technology in the industrial field, especially in the general trend of miniaturization of components, wire thickness and wire diameter has been reduced to 0.004 inches, traditional crimping, welding and copper welding techniques are gradually exposed to high connection resistance, poor reliability and short service life.

2. Mingyu Laser: Solve the problem of copper microwelding

(1) Challenges of copper materials

Copper, a commonly used conductive material in electrical connections, is favored for its excellent signal transmission ability. However, the high thermal conductivity of copper has become a problem in the microwelding process, which makes it difficult to maintain the balance of heat in the welding process, increasing the difficulty of welding.

(2) Mingyu laser solutions

In order to overcome this problem, Mingyu Laser, with its deep technical accumulation and innovation strength, has launched micro-welding technology specifically for small and highly conductive parts. By using 532 nanometers (nm) or green light wavelengths, Mingyu laser technology can precisely control the heat distribution during the welding process, ensuring the quality of the welded joint while effectively avoiding overheating or underheating problems.

3. Mingyu Laser: Breakthroughs and advantages of micro-welding technology

Compared with traditional micro-welding technologies (such as ultrasonic welding, resistance welding, etc.), Mingyu laser welding technology has made significant breakthroughs in the field of micro-welding with its advantages of high precision, high efficiency and high reliability. Whether it is welding speed, connection strength or welding quality, Mingyu laser welding technology has demonstrated excellent performance.

4. Mingyu laser ultrasonic welding technology detailed explanation

(1) Technical principles

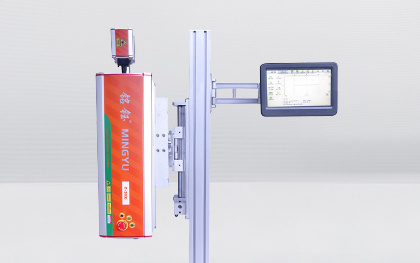

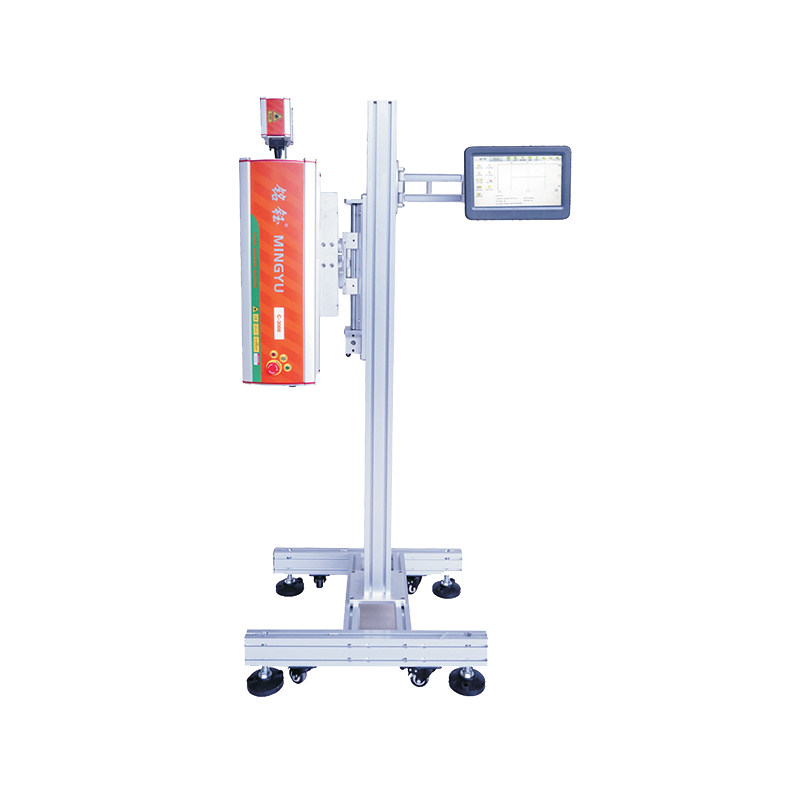

Mingyu Laser Ultrasonic welding technology (FIG. 1) uses vibration energy to weld at the connection interface. The vibration energy transmitted to the interface is provided by an ultrasonic generator or welding head that touches the top component. The welding head vibrates hundreds of times per second, with motion amplitudes between 0.0005 and 0.004 inches. The lower side of the component is provided with stable support by a "base anvil", which can be designed to be static or vibrating as required.

(2) Welding process

At the same time as the force is applied, the vibration action causes the plastic deformation of the uneven surface at the welding interface, resulting in a highly close contact and the diffusion of metal atoms. This connection allows for a high-quality connection without melting the material, while maintaining component integrity. In addition, the stability and reliability of the welded joint can be further ensured by strengthening the friction through the pressure pattern on the welding head.

(3) Technical advantages

With its unique advantages, Mingyu laser ultrasonic welding technology has shown great potential in the field of micro-welding. It can not only meet the requirements of high-precision and high-efficiency welding, but also ensure the stability and reliability of welded joints. With the continuous development and improvement of the technology, Mingyu laser ultrasonic welding technology will play a more important role in the field of electrical connection in the future.

News classification

Related News

Related News