-

-

显示更多

-

显示更多

-

显示更多

-

显示更多

-

显示更多

-

显示更多

-

ABOUT US

Comparison of laser marking and different marking methods

Release time:2024-08-24

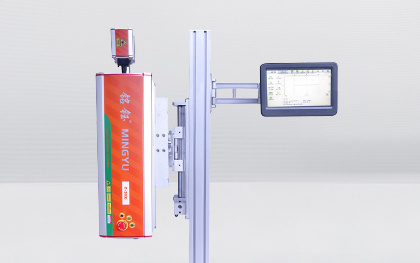

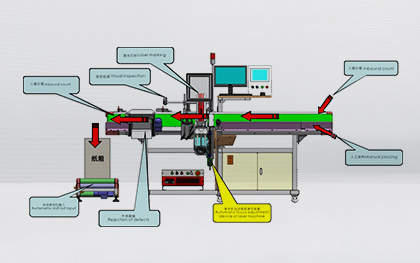

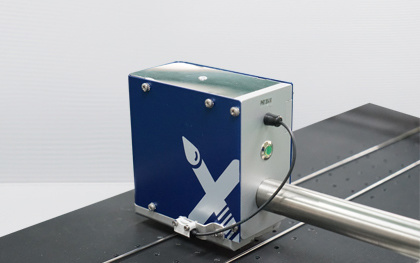

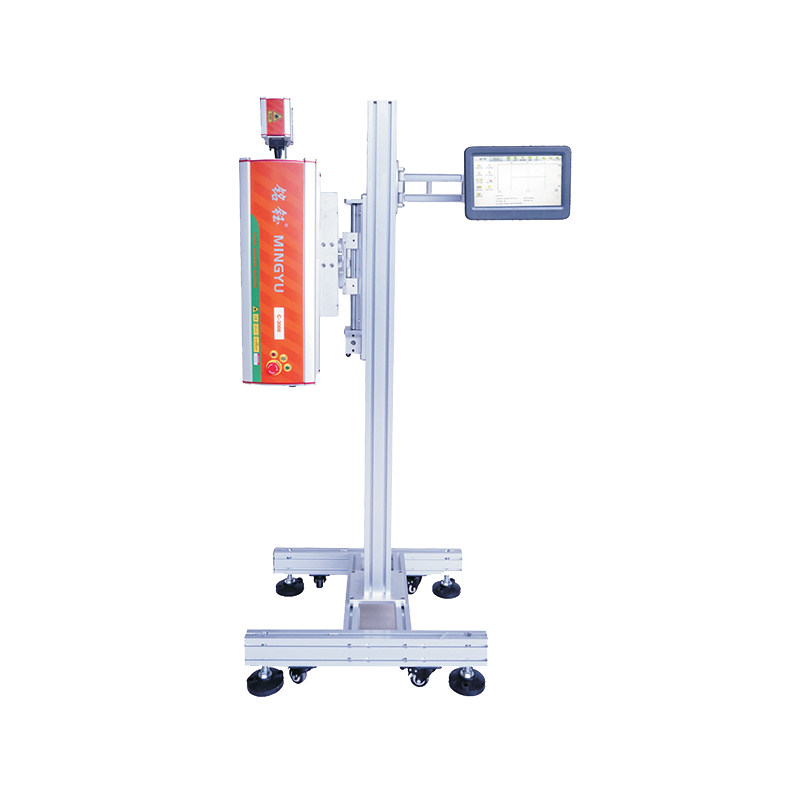

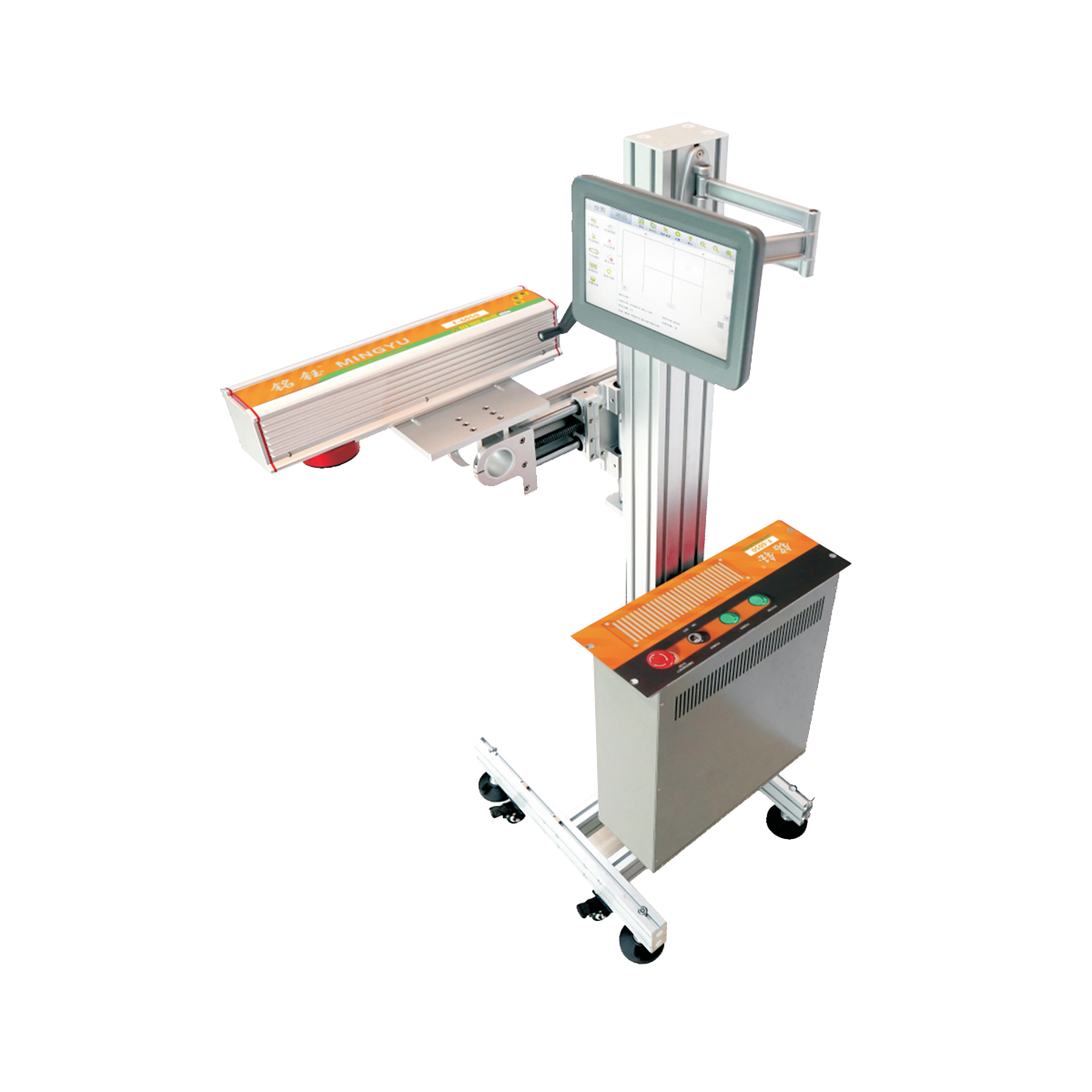

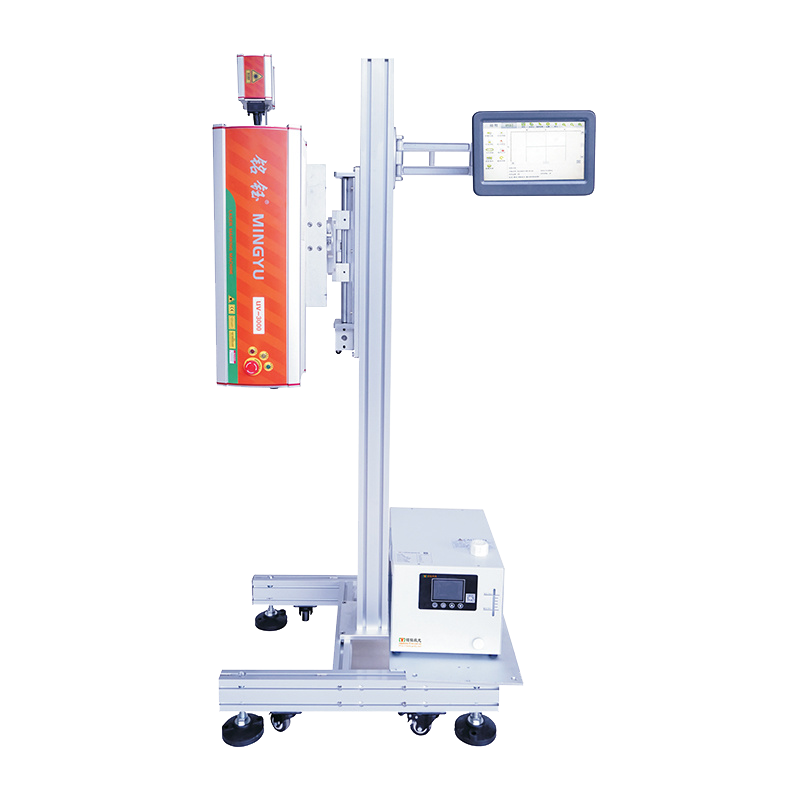

In modern industry, various marking methods are widely used in product identification, brand publicity and other fields. Among them, Mingyu laser marking technology stands out among many marking methods with its unique advantages. Below, we will compare Mingyu laser marking with several other common marking methods.

1. Application scope

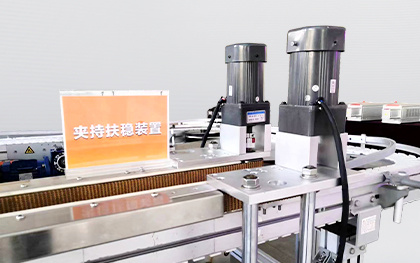

Compared with other marking methods, Mingyu laser marking has a wider range of applications. Whether it is metal, glass, ceramic, plastic or leather materials, Mingyu laser marking can be easily dealt with to achieve high-quality, permanent marking effects.

Second, the impact on the surface of the workpiece

Ming Yu laser marking: no force on the surface of the workpiece, no mechanical deformation, no corrosion on the surface of the material. This non-contact processing method ensures the integrity and aesthetics of the workpiece.

Other marking methods: such as inkjet marking, mechanical indentation, etc., may produce a certain force or corrosion on the surface of the workpiece, affecting the appearance and performance of the workpiece.

Third, performance and speed comparison

Here is a comparison of the performance and speed of several common marking methods:

1. Mingyu laser marking: fast, good performance, not easy to change. Mingyu laser marking machine adopts advanced laser technology, which can achieve high-speed and high-precision marking effect, and the marking content is not easy to be tampered with.

2. Laser mask marking: fast, good performance, not easy to change. However, compared with Mingyu laser marking, its flexibility and adaptability are slightly inferior.

3. Chemical corrosion: fast speed, good performance, but not easy to change. Chemical corrosion processes can produce hazardous substances that pose a potential threat to the environment and human health.

4. Photographic corrosion: fast, good performance, but not easy to change. Similar to chemical corrosion, photographic corrosion may also have environmental pollution problems.

5. Inkjet printing: fast, but poor performance, easy to change. Inkjet printing marks content easily erased or overwritten, not suitable for long-term preservation of marking needs.

6. Mechanical indentation: fast, but poor performance, not easy to change. Mechanical indentation may cause damage or deformation to the surface of the workpiece, affecting the appearance and performance of the workpiece.

7. Investment mold: fast, good performance, but not easy to change. Investment marking is usually used for marking metal materials, but compared to laser marking, its flexibility and accuracy are slightly inferior.

Iv. Summary

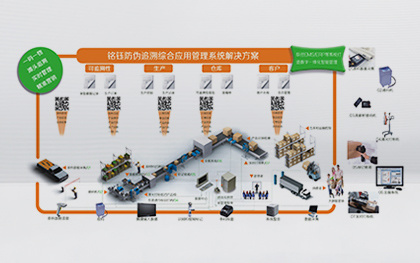

In summary, Mingyu laser marking technology has become one of the indispensable marking methods in modern industry with its wide application range, no damage to the workpiece surface, high performance and easy to change. Whether in product quality traceability, brand promotion or anti-counterfeiting labeling, Mingyu laser marking can provide customers with satisfactory solutions.

Previous Page

News classification

Related News

Related News

Guangdong Mingyu Technology Co., Ltd.

Address: Room 301-305, 3rd Floor, Building 2, No. 233 Kezhu Road, Huangpu District, Guangzhou City

Service Hotline:86-13512728673

Operator/Fax:020-85532723

Mailbox:gzmy@gzmy.net

Company website:www.gzmy.net

Public Number: Mingyu Laser, Mingyu Technology

Agency cooperation | Business opportunity follow-up | Legal statement | talent strategy | Enterprise mailbox | Proofing application