What is the laser laser marking of dairy packaging box, what is the laser laser laser requirements of dairy products?

Release time:2024-04-08

Dairy Packaging Box Laser Laser Technical Guide

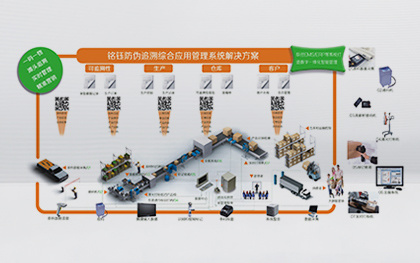

With the continuous development of science and technology, laser marking technology occupies an important position in modern industries. Especially in the field of dairy packaging, laser marking technology is gradually replacing the traditional identification method with its unique advantages. Laser marking is not only highly accurate and fast, but also can ensure product quality and bring significant economic benefits to enterprises.

Instance discussion

A well -known dairy company, while pursuing the perfectness of product packaging, also focuses on the clearness and lasting of the identification. They chose laser marking technology and identified the dairy packaging box. After practice, the technology not only improves production efficiency, but also makes the appearance of the product more beautiful.

Focus

What key issues should I pay attention to when they are laser for laser laser for dairy packaging boxes? How to operate correctly? How to ensure the quality of the logo?

Question answer

1. Key precautions

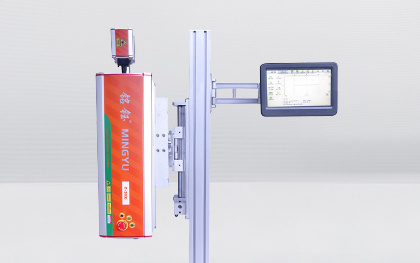

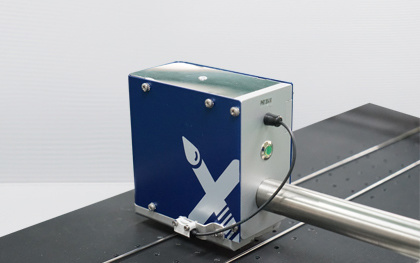

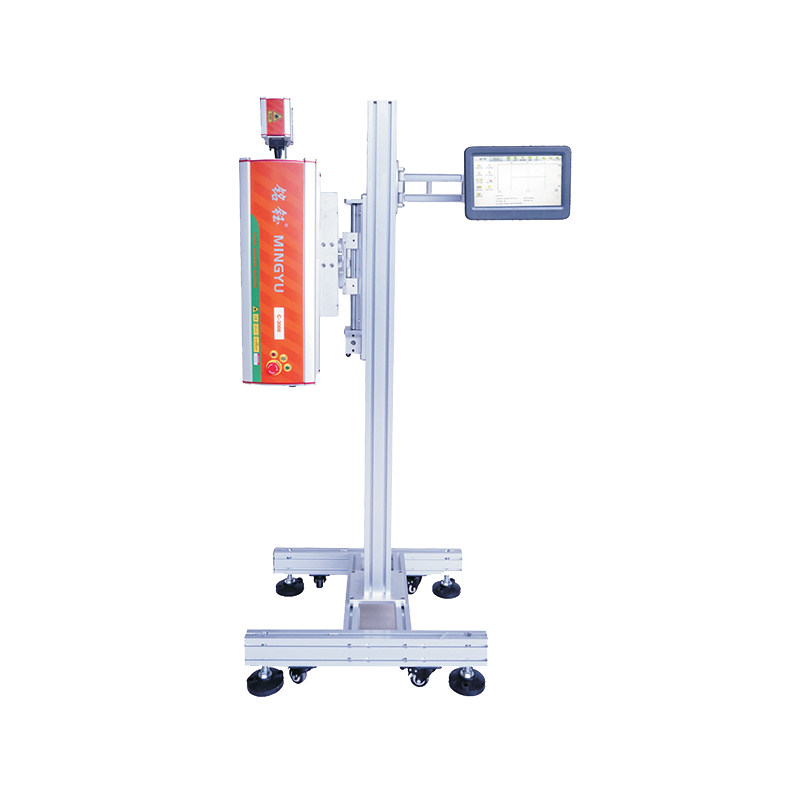

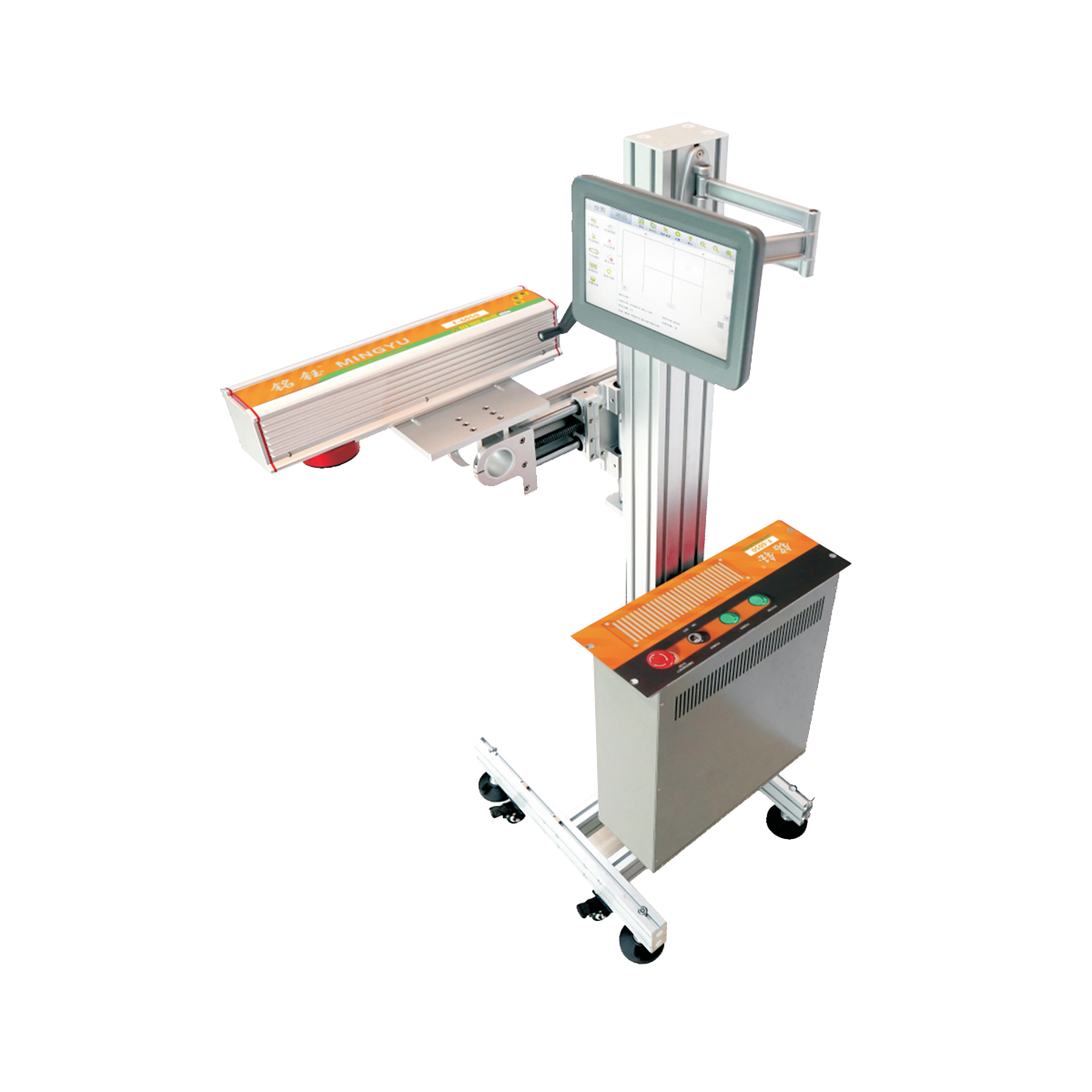

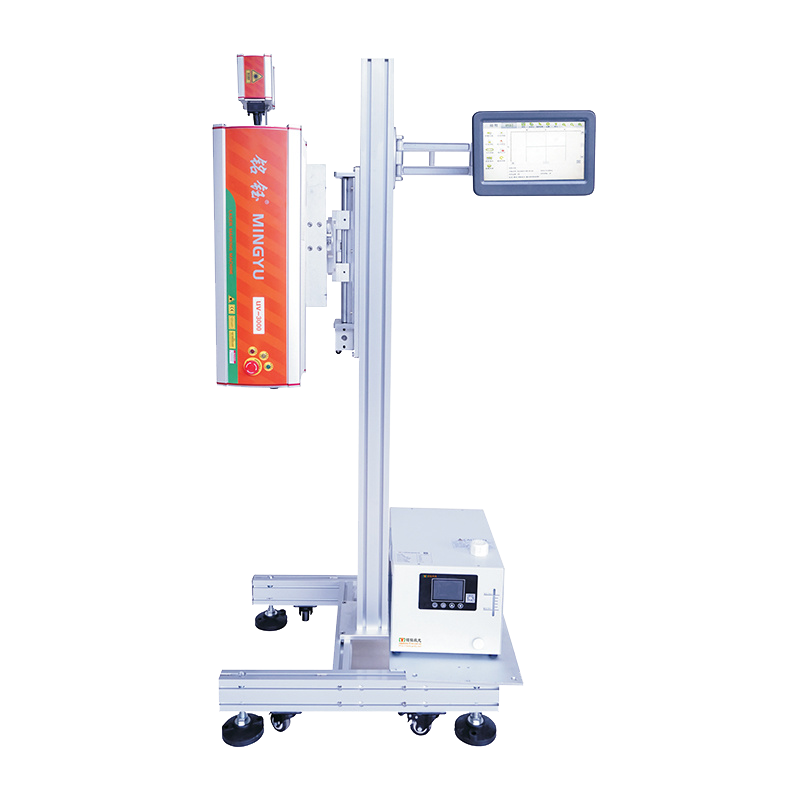

(1) Select adaptive laser marking machine. You need to choose the most suitable laser marking machine according to factors, shapes, and sizes of dairy packaging box.

(2) Equipment debugging is crucial. Before starting the marking, it is necessary to make a comprehensive debugging of the equipment to ensure that it is in the best working state.

(3) Set reasonable laser parameters. According to the material and identification requirements of the box, adjust the laser parameters to ensure that the identification effect is clear and lasting.

(4) Keep a clean operating environment. During the laser marking process, the working area and the surface of the equipment should be ensured to prevent the effects of dust and impurities on the effect of identifying the effect.

2. Operation process

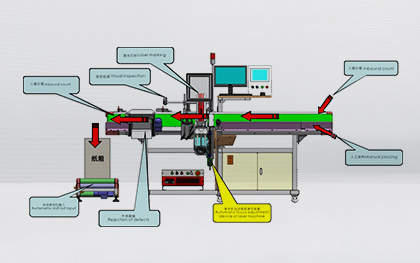

(1) Formulate a detailed marking plan. According to product characteristics and corporate requirements, clarify the elements, fonts, size and other elements.

(2) Equipment debugging preparation. Start the laser marking machine to perform necessary preheating and calibration to ensure the stable operation of the equipment.

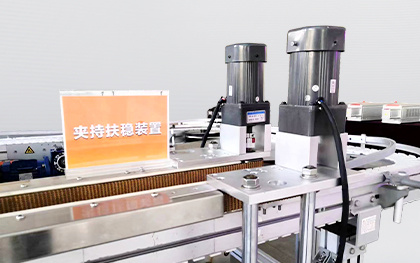

(3) Execute the marking operation. Place the dairy product packaging box in the marking machine work area, adjust the position of the laser head, and start the marking program.

(4) Check the marking results. After the marking is completed, carefully check whether the logo is clear, accurate, without omissions or vague phenomena.

3. Quality guarantee measures

(1) Use high -quality raw materials. Ensure the quality of raw materials of the dairy packaging box, laying a solid foundation for the marking effect.

(2) Strictly control the production process. From the procurement of raw materials to the finished product warehouse, each link needs to be strictly controlled to ensure product quality.

(3) Reasonably set laser parameters. For different materials and logo requirements, accurately adjust laser parameters to achieve the best label effect.

Summarize

Laser laser marking technology of dairy packaging boxes has been widely used in the dairy packaging industry with its unique advantages. This technology not only improves production efficiency, but also guarantees product quality and brings significant economic benefits to enterprises. In actual operation, we need to pay attention to key issues such as equipment selection, debugging, and parameter settings to ensure the quality of the identification. At the same time, the selection of high -quality raw materials to strictly control the production process is also a key link to ensure product quality.

Previous Page

News classification

Related News

Related News