Ink inkjet printer and laser inkjet printer comparison which is better

Release time:2023-07-19

It is not clear that everyone has the habit of checking the factory date and its shelf life when buying goods. I have to admit that the shelf life is usually fixed, but the factory date is often not easy to find. What is the matter? Since the factory date of goods is all necessary parts for printing finished products with inkjet printer after production, it is separated from the basic information of shelf life. But what I will introduce in detail for everyone today is the ink inkjet printer. Laser inkjet printer is a commodity in the new era. Its appearance is not only a major development in the technology of inkjet printer, but also a reflection of the requirements of commodity identification. The advantages of laser inkjet printer and ink inkjet printer are different, and there will be shortcomings. Who is more worth looking forward?

Ink jet printer type

1. Offset Ink

Offset printing ink, ink stable, colorful. Offset printing ink is prepared by water-based resin, can dissolve water, can be tap water diluent, the greater benefit is no solvent, reduce organic solvent evaporation, can avoid environmental pollution, does not endanger health, not easy to ignite, belonging to the energy-saving black ink. The key is offset printing ink, low price, good adhesion after printing, quick drying, strong resistance to water solubility. Generally used in food, drugs, beverages and other manufacturing industries, packaging and promotional materials manufacturing industry is also widely used.

2. oil soluble ink

Oil-soluble ink, water-soluble resin ink, not easy to dissolve water, soluble solvent. Oil soluble ink can use solvent diluent, can use digestion and absorption surface and non digestion absorption surface printing, printing is not easy to fade. Oil soluble ink characteristics of black ink viscosity, and quick drying, moisture resistance, mild, color fastness is very good. Application of black ink more economical, reasonable cost savings. Oil-soluble ink, there will also be energy-saving oil-soluble ink, can be carried out without machine-soluble code. Mostly used in metal materials, plastic, wood, aluminum platinum, cardboard boxes and decorative building materials and other materials surface.

Three, UV curing ink

Ultraviolet curing UV ink, under direct ultraviolet light, the use of different light wavelengths and different kinetic energy of ultraviolet light to make the ink emulsion and dry manic ink, connecting the individual polymers in the material to form high polymers, thus the ultraviolet curing ink has stronger mechanical equipment and organic chemical properties. UV curing UV ink key points, no organic solvent, faster drying, less energy consumption, excellent gloss, firm, colorful color, moisture resistance, water washing resistance, self-scraping resistance, suitable for high pixel, high-speed printing.

4. water soluble UV black ink

Water-soluble UV black ink is a new direction for scientific research in the UV black ink industry. Tap water and alcohol are used as paint thinners, and water-soluble UV black ink is more environmentally friendly. At this stage of the application of UV ink, most of the specific paint diluent must be added, long-term touch harm to physical and mental health, the natural environment must be environmental pollution. Water-soluble UV black ink product development is necessary and has been used in some high-regulation manufacturing industries.

5. high temperature ink

High temperature ink, part of the unique commodity to go through the high temperature of the natural environment, such as laminated glass, soldering and other manufacturing industries, must be applied high temperature ink. Generally, the ink will produce physics or chemistry at about 100 degrees Celsius, which is not up to the heat-resistant regulations. High temperature ink heat resistance, not easy to fade, the smoothness of the code, acid and alkali resistance. Lead-free and cadmium-free, environmental protection product certification pass.

Ink jet printer characteristics

The 1. ink inkjet printer is not a capacitance grid inkjet, does not need to touch the surface of the printed block immediately, and is not easy to damage the surface or inside of the printed block.

2. ink inkjet printer, inkjet code content easy to write changes. There is a control panel, which can also be connected to a computer to make changes.

3. ink jet printer, printing faster, high efficiency, the company's preferred identification machine equipment for large total production.

4. ink inkjet printer using the manufacturing industry generally, the use of materials generally, basically all materials can be printed. Metal materials, plastic, wood, aluminum platinum, paper, plastic film, laminated glass and other materials surface can be printed, can exceed the excellent printing effect.

5. ink inkjet printer mechanical equipment low cost.

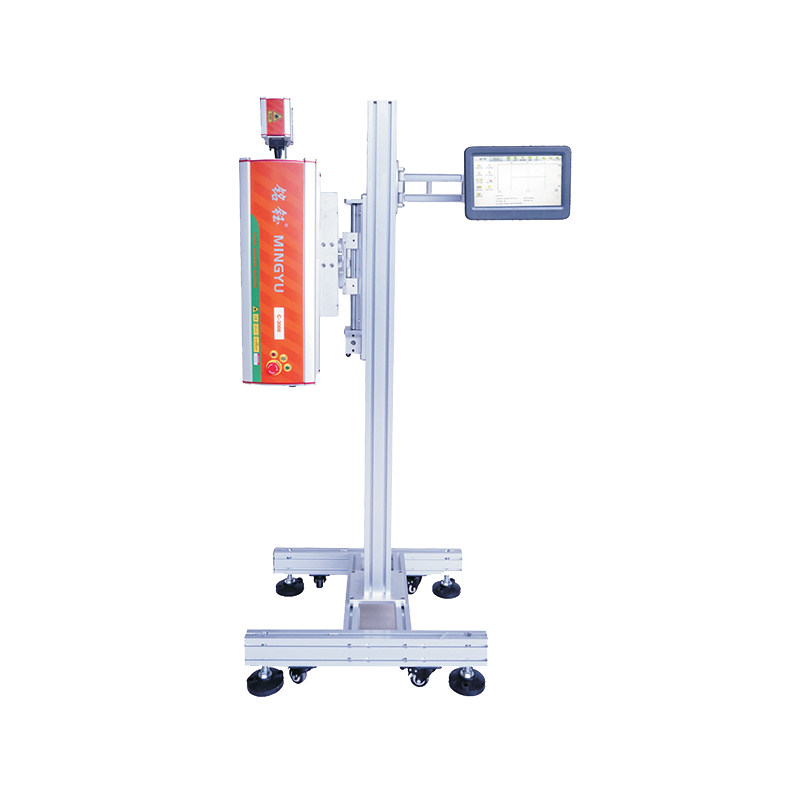

Laser inkjet printer and ink inkjet printer comparison which is more worth looking forward

1. Damage degree to steel parts

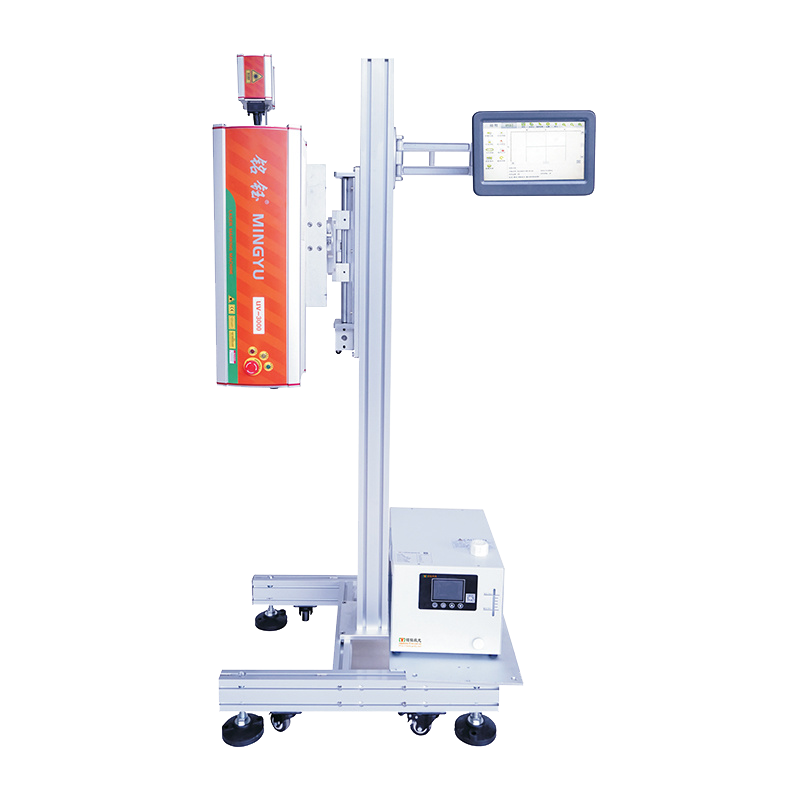

Because the inkjet printer uses organic chemical black ink to carry out contact identification, it is easy to etch the surface of steel parts. Long-term application will cause organic chemical environmental pollution to steel parts and office environment, and even cause harm to the physical and mental health of actual workers. The laser inkjet printer belongs to non-contact production and processing. The right and wrong pedal type "laser cutting knife" effect steel surface layer is not easy to cause organic chemical environmental pollution to the steel surface layer, and it is not easy to cause harm to health. Compared with environmental protection.

2. Identify the actual effect

Because the inkjet printer uses organic chemical black ink logo, the logo is easy to dissipate slowly due to the hazards of natural environment such as touch, strong acid, strong alkali vapor, temperature, etc., which cannot be maintained for a long time and the picture quality is not high. The laser inkjet printer uses the basic principle of converting light energy into energy to produce marks on the surface of steel parts, so the marks are not easy to dissipate slowly due to the hazards of external elements and belong to permanent marks; hand-carved together with high precision, the minimum graphic boundary reaches 0.04mm, the logo is exquisite, the picture quality is high, and it has anti-counterfeiting identification.

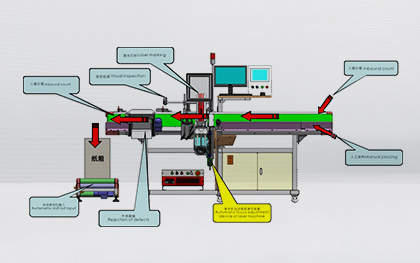

3. Identification rate

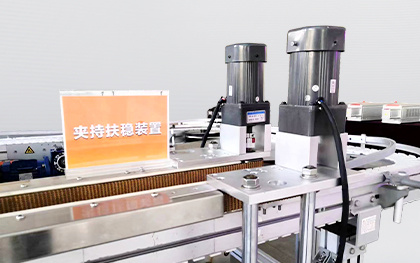

The inkjet printer uses manual service or foot-operated actual operation, which can maintain 1 line or several lines of space character identification, and the relativity is very slow. The laser inkjet printer uses an electronic computer integrated intelligent system for actual operation, which can maintain full-automatic feeding, full-automatic identification and full-automatic discharging, and reasonably arrange the time. The marking speed is quite fast, and it can keep the production capacity of thousands or even thousands of pieces per shift.

4. Operating cost

Inkjet printer machine ink consumption is large, marking a large amount of 1-year consumption costs up to more than 80000 yuan, and consumption of manual services must continue to add ink, operating costs increase. The laser inkjet printer has a small amount of consumables, most of which are non-consumable, microcomputer-based practical operation, saving manual service, and extremely low operating costs.

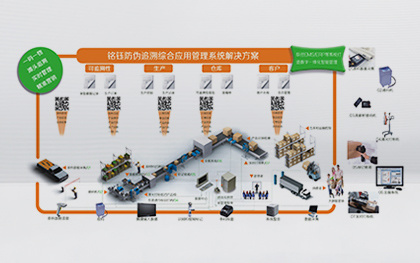

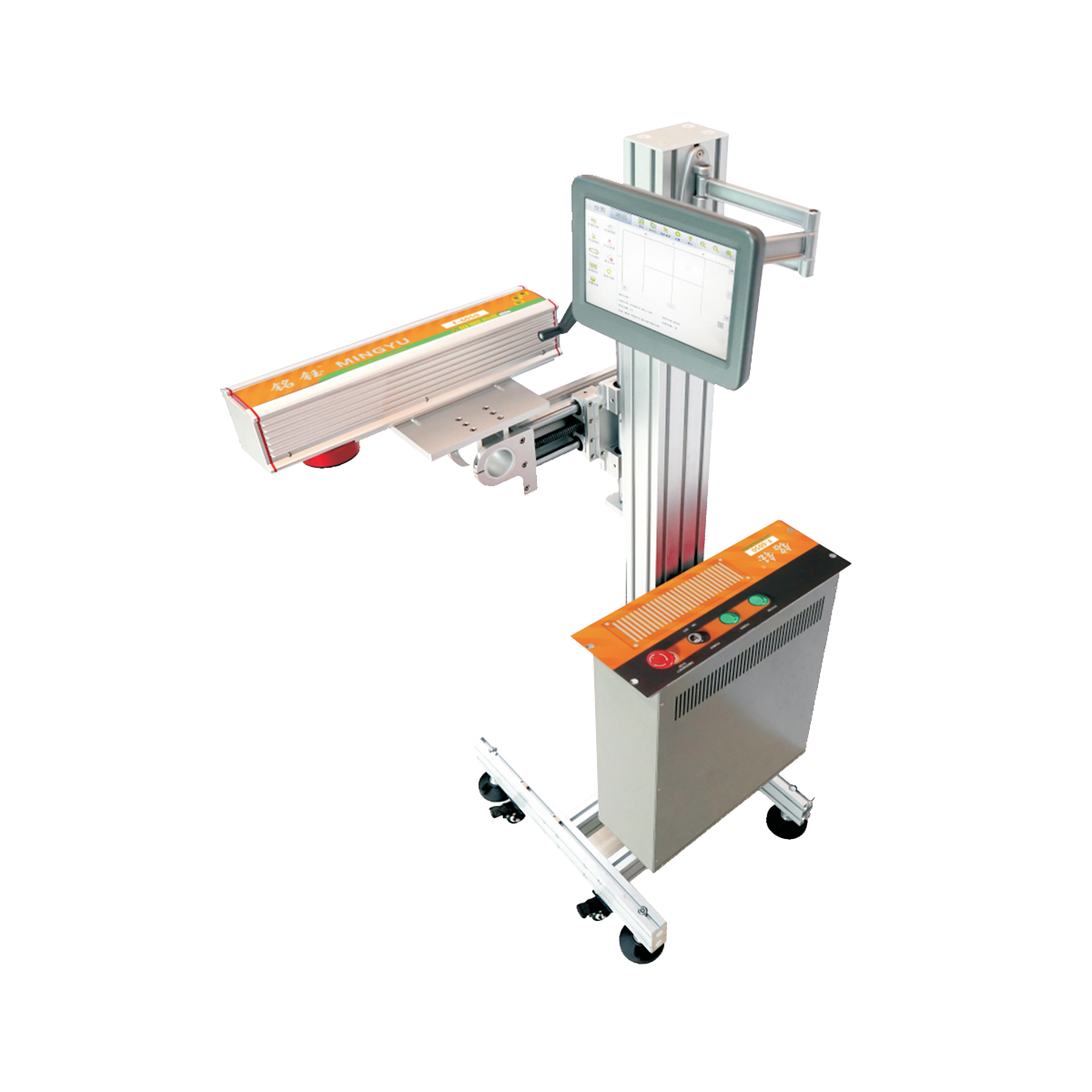

5. Convenience of actual operation

Inkjet printers have many technological processes, black ink must be continuously added, and nozzles must be cleaned frequently for maintenance and storage. Some must choose and buy consumables from specific manufacturers, which will cause inconvenience to actual operation. The laser inkjet printer has a high level of integration, which can keep the automation technology free online aviation laser marking and reduce the technological process. Moreover, the development and design are faster, the identification can be continuously removed and replaced, the storage volume is large, most of them are not maintained, and the actual operation is simple and changeable.

6. Period of use

If the inkjet printer does not often clean the nozzle, the use of the equipment is vulnerable to harm, the repair rate is also relatively high, the service life is short. Laser inkjet printer can be used for a long time, with a long service life and a working time of 100000 hours (more than 10 years).

7, the price level

Inkjet printer machine a capital investment is low, the price relativity is cost-effective, but the cost of individual steel identification is higher, the annual average capital investment fixed cost is higher (labor service, consumption, average price). Laser inkjet printer a capital investment is higher, the price is relatively expensive, but the cost of separate identification is lower, the annual average capital investment fixed cost is lower (labor service, consumption, average price).

8. Acceptability

The inkjet printer is suitable for commodities with low non-metallic materials, such as food, beverage, pharmaceutical packaging, etc. However, some metal products such as stainless steel plates cannot be marked. Laser inkjet printer can select various models according to steel materials, which are suitable for identification of metal materials and hard plastic non-metal materials.

News classification

Related News

Related News