Types and differences of laser marking machine

Release time:2023-07-19

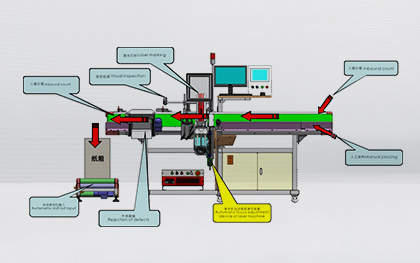

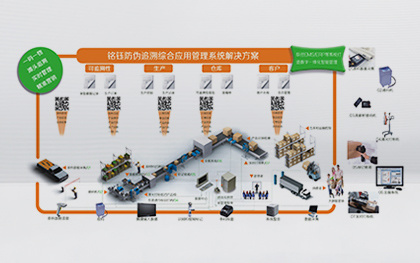

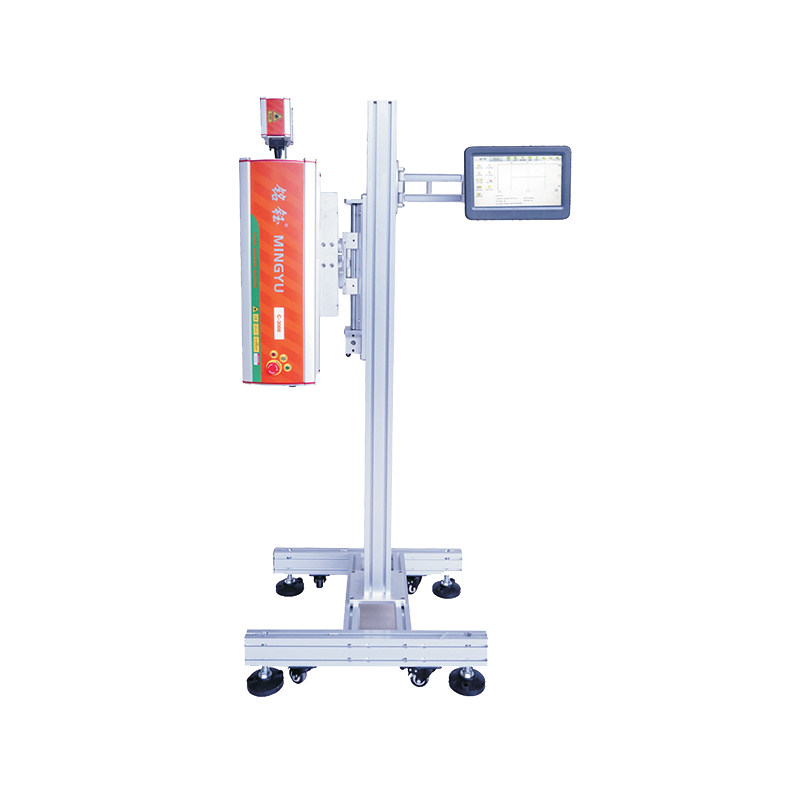

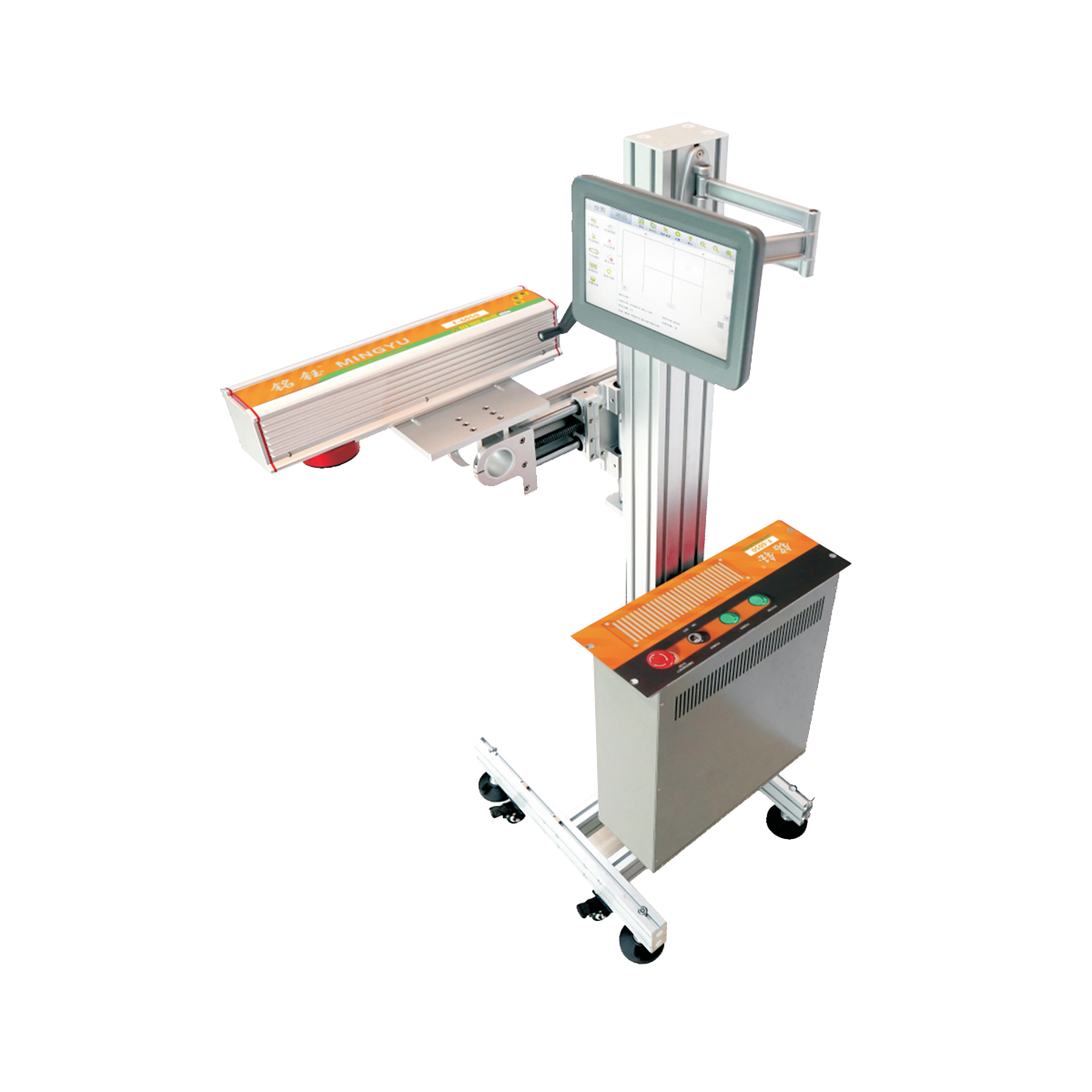

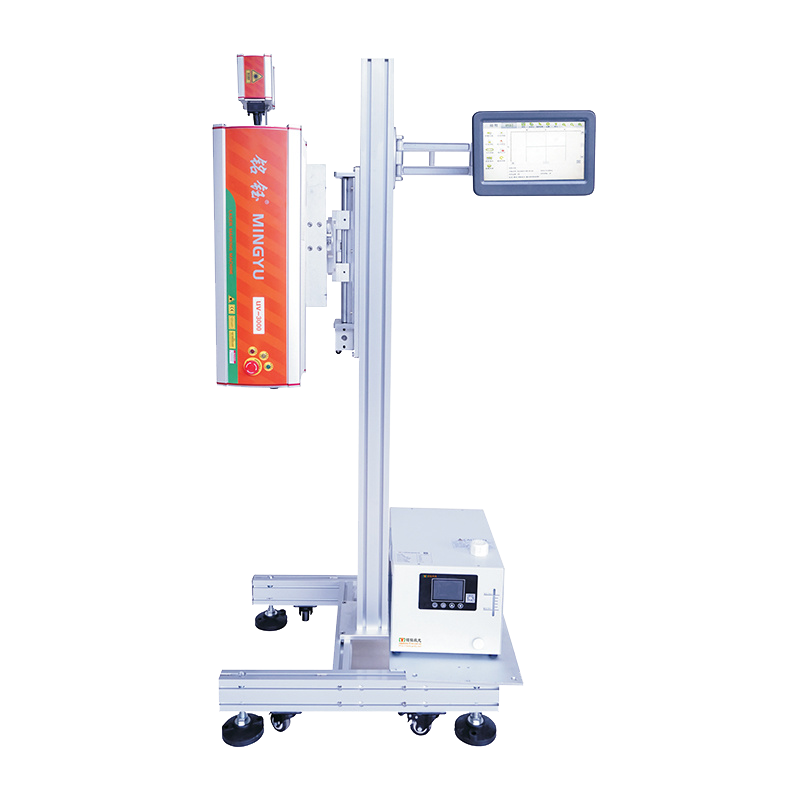

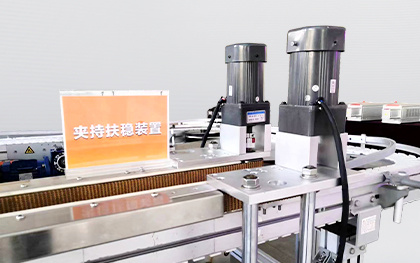

Laser marking machine, in simple terms, is the use of laser beam through the optical system focused on the marking machine on the worktable, the marked text or pattern on the surface of the workpiece for carving, engraving equipment. With the continuous development of science and technology, there are many kinds of laser marking machines with different performances. This article will classify and distinguish the common laser marking machines on the market, hoping to help readers understand the working principle and performance characteristics of laser marking machines through this article.

1. laser marking machine classification

1. According to the type of laser light source

Laser light sources can be divided into solid lasers, gas lasers and special lasers. Solid lasers include red lasers, green lasers, blue lasers, etc.; gas lasers include YAG lasers, UV lasers, etc.; special lasers include CO lasers, Nd:YAG lasers, etc.

2. According to the laser marking machine power division

The greater the power of the laser marking machine, the faster the processing speed and the higher the scoring accuracy. Under normal circumstances, the power of the laser marking machine can be divided into three categories: low power, medium power and high power.

3. According to the laser marking machine mechanical structure division

The mechanical structure of the laser marking machine is mainly divided into precision guide rail structure, ordinary guide rail structure and high precision guide rail structure. The precision guide rail structure is mainly used in the field of high-precision processing. The parallel guide rail layout can realize the parallelism error of the optical path within ± 2μm; the ordinary guide rail structure is suitable for general processing requirements, and the optical path error is controlled within ± 10μm; the high-precision guide rail structure is mainly used in the field of high-precision processing, and the optical path error can be controlled within ± 5μm.

4. According to the laser marking machine interface type division

The interface types of laser marking machine are mainly divided into USB interface, RS-232 interface, network port and optical interface.

2. laser marking machine performance difference

1. The power and wavelength of the laser light source

The greater the power of the laser light source, the higher the energy of the beam, which can provide more photons, so that the number of photons per unit area increases, thereby improving the speed and accuracy of the scribing. The wavelength of the laser light source determines the focusing degree of the beam, and the adjustment of the beam energy can be realized by adjusting the wavelength.

2. Processing speed of laser marking machine

The processing speed of the laser marking machine mainly depends on the precision of its working system. The more precise the working system, the faster the switching speed and the faster the processing speed.

3. Laser marking machine scoring accuracy

The marking accuracy of the laser marking machine mainly depends on the power of the laser light source, the focusing degree of the beam and the precision of the working system. Higher power and more precise focusing can improve the scoring accuracy.

4. Durability of laser marking machine

The working environment of laser marking machine is complex and changeable, so its durability is very important to ensure its normal use. At the same time, the laser marking machine has a long working time every day, so it needs to have better durability to reduce the failure rate.

5. The maintainability of laser marking machine

The laser marking machine needs to be maintained regularly to ensure its performance and stability. Maintenance includes cleaning the laser, replacing consumables, etc.

3. purchase laser marking machine matters needing attention

1. Select the appropriate laser light source according to the workpiece material

Different materials of the workpiece on the laser absorption, reflection and other characteristics are different, choose the appropriate laser light source can improve the processing effect of laser marking machine.

2. Consider the power and performance of the laser marking machine

The appropriate power and performance of the laser marking machine can ensure that the workpiece is processed within the specified time and improve production efficiency.

3. Confirm the interface type of laser marking machine

The interface type mainly affects the stability of data transmission and work, and the appropriate interface type should be selected according to actual needs.

4. Select high quality parts

The precision structure and key components of the laser marking machine need to ensure its durability and reliability, so high-quality parts should be selected.

5. Provide adequate training and technical support

After the purchase of laser marking machine, the operator should be fully trained to ensure its skilled use. At the same time, manufacturers with perfect after-sales service and technical support should be selected to ensure that problems encountered during use are resolved in a timely manner.

In short, there are many types of laser marking machines with different performances. When purchasing, it is necessary to comprehensively consider factors such as workpiece material, laser light source power and performance, interface type, component quality, and after-sales service to ensure that the appropriate laser marking machine is selected to achieve efficient and stable processing.

Previous Page

Next Page

Previous Page

Next Page

News classification

Related News

Related News