-

-

显示更多

-

显示更多

-

显示更多

-

显示更多

-

显示更多

-

显示更多

-

About Dexin

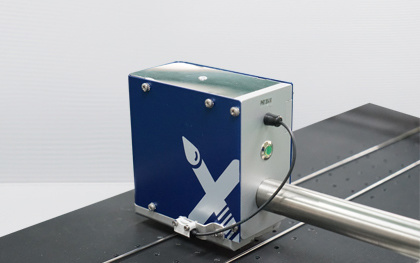

PLC Interface

PLC interface is an important technology in the marking machine software system, which realizes the data interaction and control instruction transmission between the marking machine and the programmable logic controller (PLC). Through the PLC interface, users can easily integrate the marking machine with the PLC to achieve more advanced automation control and operation.

The PLC interface uses standardized communication protocols, such as Modbus, Profibus, etc., to ensure that different brands and models of PLC equipment can be seamlessly connected. This compatibility allows users to freely choose the PLC equipment that suits their needs, and improves the flexibility and scalability of the system.

In practical applications, the PLC interface can achieve a variety of functions. It can use PLC as a host computer to control the motion trajectory, speed and power of the marking machine. By writing corresponding programs, users can achieve complex graphics and text marking tasks, improve production efficiency and product quality.

The PLC interface can also realize the condition monitoring and fault diagnosis of the marking machine. Through real-time communication with PLC, the marking machine software can obtain the working status, error code and other information of the machine, and provide alarm prompt and troubleshooting guidance to the user in time. This greatly improves the reliability and maintenance efficiency of the equipment.

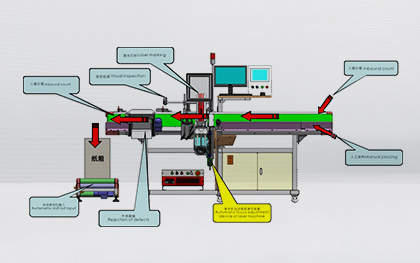

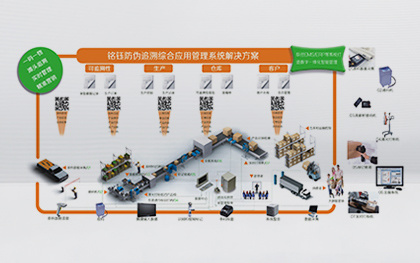

In addition, the PLC interface can be integrated with other industrial equipment and systems. For example, the marking machine can be linked with sensors, pneumatic components, visual recognition systems and other equipment on the production line to achieve a comprehensive automated production process. This not only reduces the need for manual intervention, but also improves the continuity and stability of production.

In short, PLC interface, as a key technology of marking machine software system, provides users with more powerful and flexible control and management functions. Its application can not only improve production efficiency and product quality, but also reduce production costs and maintenance costs, and create greater economic benefits for enterprises.

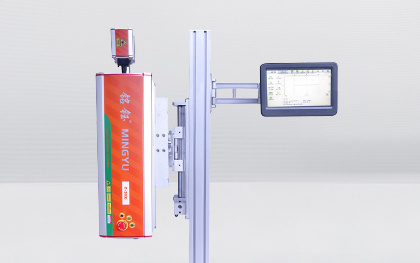

Guangdong Mingyu Technology Co., Ltd.

Address: Room 301-305, 3rd Floor, Building 2, No. 233 Kezhu Road, Huangpu District, Guangzhou City

Service Hotline:86-13512728673

Operator/Fax:020-85532723

Mailbox:gzmy@gzmy.net

Company website:www.gzmy.net

Public Number: Mingyu Laser, Mingyu Technology

Agency cooperation | Business opportunity follow-up | Legal statement | talent strategy | Enterprise mailbox | Proofing application