The utility model provides a clamping and pressing device for carton packaging, which comprises a conveyor belt for conveying the carton to be clamped and pressed, and further comprises: a bracket, several clamping cylinders and a pressing cylinder; the bracket is sleeved on the conveyor belt, and the bracket is square; several clamping cylinders are fixed on the measuring rod of the bracket, and several clamping cylinders are symmetrically arranged on the measuring rod of the bracket, A plurality of push rods of the clamping cylinder are arranged opposite to each other on both sides of the conveyor belt; the pressing cylinder is fixed on the top of the bracket, and the push rod of the pressing cylinder is arranged downward. The clamping and pressing device for carton packaging provided by the utility model is convenient and fast to operate, high efficiency, high operational stability, and the back-end sealing operation improves the automation and production efficiency of the entire product production line. It can be widely used in the field of automatic packing.

The utility model provides a clamping and pressing device for carton packaging, which comprises a conveyor belt for conveying the carton to be clamped and pressed, and further comprises: a bracket, several clamping cylinders and a pressing cylinder; the bracket is sleeved on the conveyor belt, and the bracket is square; several clamping cylinders are fixed on the measuring rod of the bracket, and several clamping cylinders are symmetrically arranged on the measuring rod of the bracket, A plurality of push rods of the clamping cylinder are arranged opposite to each other on both sides of the conveyor belt; the pressing cylinder is fixed on the top of the bracket, and the push rod of the pressing cylinder is arranged downward. The clamping and pressing device for carton packaging provided by the utility model is convenient and fast to operate, high efficiency, high operational stability, and the back-end sealing operation improves the automation and production efficiency of the entire product production line. It can be widely used in the field of automatic packing.

The utility model provides a clamping and pressing device for carton packaging, which comprises a conveyor belt for conveying the carton to be clamped and pressed, and further comprises: a bracket, several clamping cylinders and a pressing cylinder; the bracket is sleeved on the conveyor belt, and the bracket is square; several clamping cylinders are fixed on the measuring rod of the bracket, and several clamping cylinders are symmetrically arranged on the measuring rod of the bracket, A plurality of push rods of the clamping cylinder are arranged opposite to each other on both sides of the conveyor belt; the pressing cylinder is fixed on the top of the bracket, and the push rod of the pressing cylinder is arranged downward. The clamping and pressing device for carton packaging provided by the utility model is convenient and fast to operate, high efficiency, high operational stability, and the back-end sealing operation improves the automation and production efficiency of the entire product production line. It can be widely used in the field of automatic packing.

The utility model provides a clamping and pressing device for carton packaging, which comprises a conveyor belt for conveying the carton to be clamped and pressed, and further comprises: a bracket, several clamping cylinders and a pressing cylinder; the bracket is sleeved on the conveyor belt, and the bracket is square; several clamping cylinders are fixed on the measuring rod of the bracket, and several clamping cylinders are symmetrically arranged on the measuring rod of the bracket, A plurality of push rods of the clamping cylinder are arranged opposite to each other on both sides of the conveyor belt; the pressing cylinder is fixed on the top of the bracket, and the push rod of the pressing cylinder is arranged downward. The clamping and pressing device for carton packaging provided by the utility model is convenient and fast to operate, high efficiency, high operational stability, and the back-end sealing operation improves the automation and production efficiency of the entire product production line. It can be widely used in the field of automatic packing.

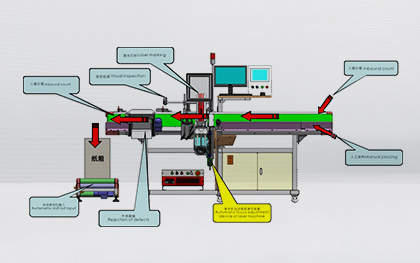

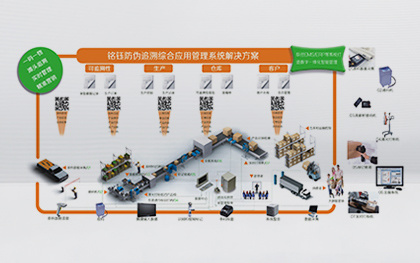

Non-standard line equipment is the user-customized, the only automation system integration equipment, is the use of the unified industry standards and specifications issued by the state manufacturing unit equipment assembly, according to the customer's use needs, development and design of manufacturing equipment. Different types of customers have different process requirements.

Non-standard line equipment is the user-customized, the only automation system integration equipment, is the use of the unified industry standards and specifications issued by the state manufacturing unit equipment assembly, according to the customer's use needs, development and design of manufacturing equipment. Different types of customers have different process requirements.

Non-standard line equipment is the user-customized, the only automation system integration equipment, is the use of the unified industry standards and specifications issued by the state manufacturing unit equipment assembly, according to the customer's use needs, development and design of manufacturing equipment. Different types of customers have different process requirements.

Non-standard line equipment is the user-customized, the only automation system integration equipment, is the use of the unified industry standards and specifications issued by the state manufacturing unit equipment assembly, according to the customer's use needs, development and design of manufacturing equipment. Different types of customers have different process requirements.

Non-standard line equipment is the user-customized, the only automation system integration equipment, is the use of the unified industry standards and specifications issued by the state manufacturing unit equipment assembly, according to the customer's use needs, development and design of manufacturing equipment. Different types of customers have different process requirements.